Shopmade Tension Gauge

Built-in bandsaw gauges are notoriously inaccurate. Here's an inexpensive tool that eliminates guesswork

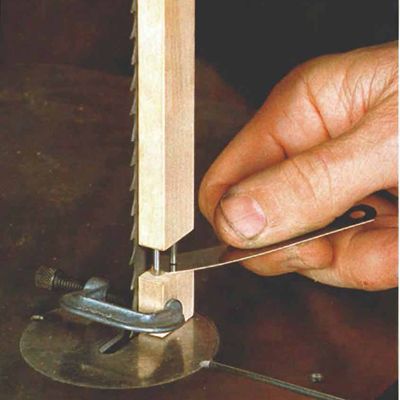

John White, Fine Woodworking’s shop manager, shows readers how to make and use a bandsaw blade-tensioning gauge. When used with an ordinary automotive feeler gauge, this shopmade tool allows you to set the correct tension on your steel blade quickly. White share plans and directions for making the gauge. He explains how to determine the right amount of tension, and how to set it properly. White also details the role of the spring in your bandsaw and offers tips on selecting a replacement.

From Fine Woodworking #147

Fine Woodworking Recommended Products

Starrett 12-in. combination square

Stanley Powerlock 16-ft. tape measure

Dustopper Pro

Log in or create an account to post a comment.

Sign up Log in