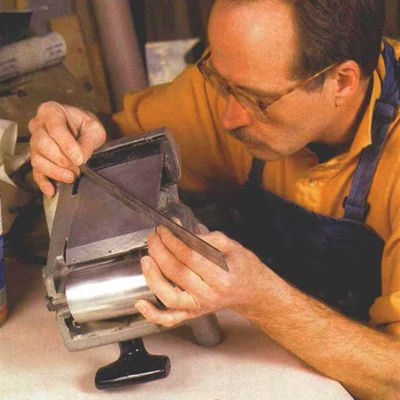

Tune Up Your Belt Sander

Tips on improving the performance of this versatile shop tool

Synopsis: A large illustration labeling the parts of a belt sander starts off Sven Hanson’s article. Hanson says that to get the best performance, a belt sander must have a flat platen, a straight-tracking belt, and the proper adhesive. He advises adding a graphite pad and enhancing the vacuum system, and he explains how he periodically removes the drive wheel and paints it with a tire-traction compound he finds at hobby stores. He discusses and shows how he tackles other maintenance as well.

From Fine Woodworking #128

To get the best, or even adequate performance, from a belt sander, it must have a flat platen, a straight-tracking belt and the proper abrasive. It will perform even better with an effective vacuum system.

When the pad area on the bottom of the sander has a twist or a high spot, one or two corners do all the work, leaving visible valleys in sanded areas. To check a used sander, or a new one before I buy it, I remove the metal friction plate and the soft pad beneath it, which is usually made of cork. I sight down the bottom as if I were sighting the sole of a handplane. The front and rear wheels should lie parallel to the platen, and the platen must be flat. I confirm this by checking the bottom with a straightedge. I pay special attention to the diagonals and look for hollows or hills on the platen, which I level with a file.

Graphite pads are far superior to the old steel-over-cork system that comes as a stock item on many sanders. The graphite pads replace the hard surface of the steel backer with a slick, spongy cloth. Graphite evens out the pressure against the workpiece and reduces friction. A graphite pad helps the sander run cooler and gives both the tool and the belt a longer life.

Klingspor (800-228-0000) and some woodworking suppliers sell graphite pads in a variety of sizes to fit different machines. They come with and without self-adhesive strips. For the best bargain, I cut pads for my belt sander from a roll of graphite made for a larger machine. I clamp a piece of graphite (without adhesive on the back) under the retainer bar and over the stock cork pad.

If the cork pad is worn down, it should also be replaced. The thicker the cork the better. Enhance vacuum system The belt sander cuts wood so effectively that it’s often sanding loose sawdust instead of the work surface. Basic maintenance should include blowing the dust out of the motor housing and exhaust ports to keep the vacuum system clear of debris. Sometimes rougher grits create clogs of dust that I break loose with a soda straw or with two or three long pipe cleaners twisted together. When working in living spaces, I reduce dust output by attaching a vacuum cleaner to the sander with duct tape. I use naphtha later to remove the excess adhesive left by the tape.

For the full article, download the PDF below.

Fine Woodworking Recommended Products

Fein Turbo II HEPA Wet/Dry Dust Extractor

Festool Cleantec CT 26 E HEPA Dust Extractor

Makita SP6000J1 Track Saw

Log in or create an account to post a comment.

Sign up Log in