Synopsis: “Colorado Slim” shares colorful stories about shooting pool and making cues, good and bad ones. He talks about the taper, diameter, stock material, and connectors that make up a good stick. A good pool cue joint, he says, should act like a shock absorber to dampen the impact of the cue and the ball, and another feature is equal distribution of weight along the stick. He explains how to glue up the handle blank and use a jackshaft setup to drill and thread the brass parts on the lathe. He rigged up a steady rest from a pillow-block bearing and turned maple sleeves to fit over different diameters along the tapered shaft and handle. He lets the wood cure for days between turnings, and saves turning the end to receive the ferrule for last. Extensive photos and drawings illustrate the detailed work involved.

It was a hot, dry August day, and we were shooting nine-ball for dollars at The Wheel, a little cowboy bar in Estes Park, Colorado. The three of us were definitely in our stride by mid-afternoon when a new guy walked in, saddled up to the bar and ordered a beer and a shot. After a while, he just seemed to fade into the crowd.

Jimmy caught the guy’s side glance at the pool table. “Hey, Slim,” he said under his breath, “I think maybe we got ourselves some action here. How do you want to play it?” If I turned around I’d play my hand, so I waited for my turn on the table to get a better look. Cody was on a roll, and I began to wonder if he was going to scare this fellow off before we’d had a chance to see his dance. Cody wowed the crowd with a three-rail slice into the corner and calmly asked if we’d like to up the stakes. “Nice shot, cowboy,” I said as I got up to rack the balls.

The new guy was a real sleeper. He looked good from a distance; almost indifferent, but confident. He was laying back just checking things out. One thing for sure, he was learning more about us than we were about him and that didn’t sit good with me at all. Got to get him off that stool before the stakes get too high and he runs. Got to see him bridge that cue—just once— then I’d know for sure. It was time to put on the squeeze.

I slipped Jimmy a twenty that I’d folded around a dime and whispered, “You’re out.” (The twenty was for beer. . .the dime let him know he’d get ten percent of the take.) “OK, Cody, $5 and $5, with re-spots only on the nine.” I said. If I lost, it was on my shoulders. Cody was ready to flip for the break when the new guy finally opened up. . . “You fellows want a third?”

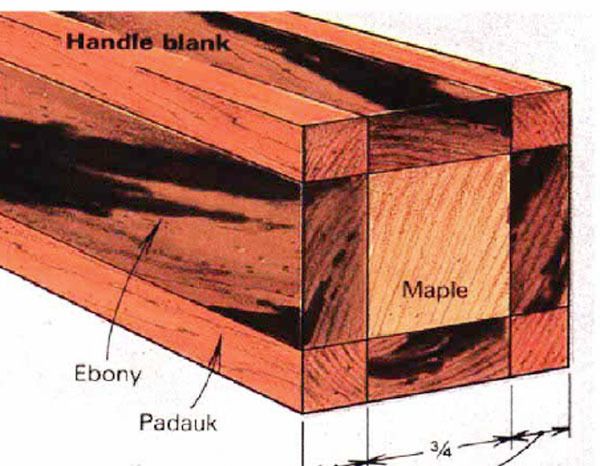

I started playing pool in 1958. By 1965, after three years with Uncle Sam, I was hot stuff. I made my first cue stick in 1970. It was a beauty—rosewood, maple, ebony, purpleheart, mother-of pearl inlays in the handle—everything I’d seen in other cues, and more. The shaft was the best part; bright red padauk. When I walked into a hall with that stick it was “eyes RIGHT!” It didn’t matter if I was good or not; this was a lesson in intimidation.

From Fine Woodworking #59

For the full article, download the PDF below:

Log in or create an account to post a comment.

Sign up Log in