Powermatic - Powermatic – PM 2800 Drill Press

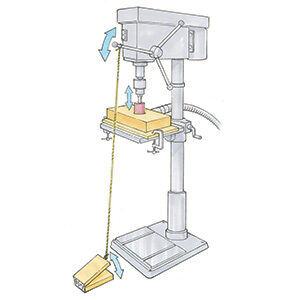

The PM 2800 drill press offers easy-to-adjust variable speed control and digital readout

Powermatic’s new model 2800 drill press is a precision drilling machine with lots of convenient features.

It offers easy-to-adjust variable speed control and accompanying digital readout. The 1-hp motor provides adequate power for big bits—even hole saws. In fact, I had no problem boring a 41/8-in.-dia. hole through 5/4 hard maple.

The large cast-iron table features sliding extensions that create an even bigger worksurface. T-slots in the table accommodate an aluminum adjustable split fence, which includes a 2-in. dust port, and provide the possibility of creating custom hold-downs. Other convenient features are the twin LED lights that illuminate the work, laser crosshairs for pinpoint drill positioning, a large lighted power switch on the front, and feed handles that can be configured for a right- or left-handed operator. A keyless 5/8-in. chuck offers big capacity and quick, secure bit changes, and a double-nut locked depth gauge assures accurate repeatability.

The table tilts left or right, but operating the tilt mechanism requires a socket wrench—an inconvenience. Also, a lock pin positions it at 0°, 45°, or 90°, but the pin had about 4° of play at each position.

For the money ($900), the PM 2800 is powerful, precise, and convenient, with only the table-tilt falling short.

Photo: Roland Johnson

Log in or create an account to post a comment.

Sign up Log in