Jet - 18-in. Bandsaw JWBS-18X

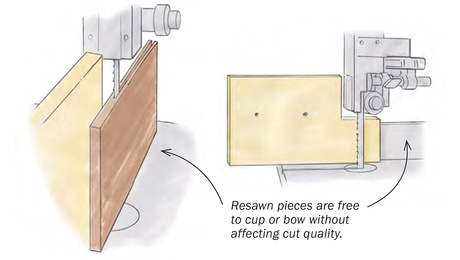

The WMH Tool Group unveiled this redesigned 18-in. Jet bandsaw with a 12-in. resaw capacity and a number of improvements over the previous 18-in. model (JWBS-18).

The WMH Tool Group recently unveiled its redesigned 18-in. Jet bandsaw with a 12-in. resaw capacity. The saw has many significant improvements over the previous 18-in. model (JWBS-18).

A much stiffer frame and a beefier upper guide-post mount result in lower flex numbers. The lower blade guides have been redesigned to make adjustments easier and more accurate. All adjustments are toolless except for the thumbscrew that secures the thrust bearing, which requires pliers to tighten it sufficiently. Table flex has been improved through the use of heavier trunnions. The table locks in position more positively with large knobs.

Jet has increased the power to 1-3/4 hp, compared to 1-1/2 hp for the previous model. With a maximum blade-width capacity of 1-1/2 in., the power is welcome. A window in the upper wheel housing allows you to adjust blade tracking with the machine on and cover door closed.

Log in or create an account to post a comment.

Sign up Log in