Get It All!

UNLIMITED Membership is like taking a master class in woodworking for less than $10 a month.

Start Your Free TrialUp Next

Featured Workshop

With its graceful curves, cabriole legs, and ornamental back splat, a Queen Anne side chair is a bucket list build for many woodworkers. Dan Faia had a very specific Queen…

Featured Projects & Plans

Discussion Forum

Highlights

-

Shape Your Skills

when you sign up for our emails

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply. -

Shop Talk Live Podcast

Shop Talk Live Podcast -

Our favorite articles and videos

Our favorite articles and videos -

E-Learning Courses from Fine Woodworking

-

-

Comments

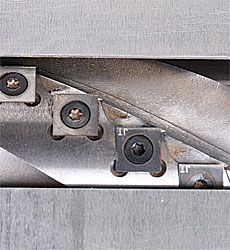

The spiral cutter shaft requires less horsepower, makes smaller chips and less noise than any other type of cutterheads do. Meanwhile it has high rotation speed, long edge life, easy replacement of knives, and in-machine grinding and jointing, avoid long time cutterhead maintenance.

Log in or create an account to post a comment.

Sign up Log in