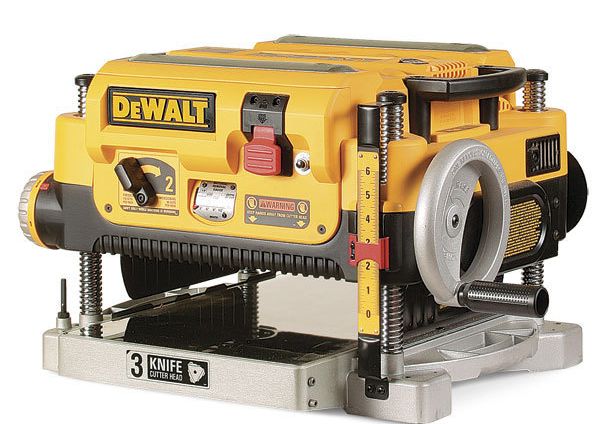

DeWalt - DeWalt 735 Benchtop Planer

DeWalt’s 13-in. planer features a three-knife cutterhead and a built-in chip extraction system

The DeWalt 735X produced two faces perfectly parallel to one another, with surfaces far superior to what the other machines produced, thanks to its two feed speeds. At high speed, the planer works fast and leaves a smooth surface. But the slower, finish speed produces an almost glass-smooth surface. Knife changes are easy, with spacious access to the cutterhead from the top and a gib screw wrench that doubles as a magnetic lift to remove the knives. The 735X also has great dust collection, thanks to an internal blower that helps evacuate chips. The port has a 21⁄2-in.-dia. opening, but has a built-in adapter for 4-in.-dia. hoses. My only complaint is the location of the dust port. It’s on the outfeed side of the machine, and exits straight back. If you don’t pull the hose to the side, it interferes with material as it leaves the machine. The top is large and flat, so it’s a great place to set material in between passes through the machine.

Comments

I've owned this model and used it for 2 years. It works great. I had read several reviews that complained about the short life of the blades and lines left on the stock. I've found the thickness of the cut is the key. I'm very happy with it.

Log in or create an account to post a comment.

Sign up Log in