Bridgewood - 1-hp. Mortiser MS-10

The Bridgewood mortiser features a 1 hp motor and a 6 1/2 in. by 20 in. cast-iron table.

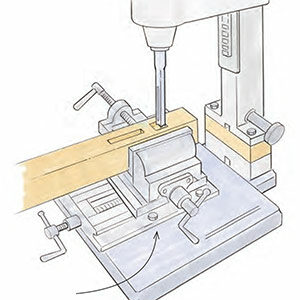

Large stand-alone mortisers have been around for nearly a century, but now several manufacturers offer more affordable stand-alone models with features that make them practical for serious hobbyists and small commercial shops. Compared with the drill-press add-ons and benchtop mortisers currently on the market, these mortisers feature lots of cast-iron tables that move, sturdy hold-downs, 1-hp motors, and extralong lever handles. Curious to find out just how well these machines work, I tested seven of them.

All things considered, I was pleased to find that all seven were well made and did a decent job cutting accurate mortises, even when running a 3/4-in. bit. That puts them head and shoulders above any of the drill-press add-ons or benchtop mortisers I’ve used. So it wasn’t easy to choose a favorite.

The Bridgewood, Geetech, Grizzly, and Woodtek machines look very much alike, except for paint color. Even the owner’s manuals are identical. They use a large handwheel on the front to move the table side to side and forward and backward. The mortising head is raised with a long lever, which is pinned in place on these machines (I prefer an adjustable lever). All these machines did an adequate job boring any size mortise up to 3/4 in. Their hold-down systems worked great, the tables moved smoothly, and the stops for the table and mortise head worked satisfactorily. Bit changes were relatively easy. The Grizzly has a 110-volt motor, but you need a 240-volt circuit for the Bridgewood, Geetech, and Woodtek machines.

Log in or create an account to post a comment.

Sign up Log in