All About Planers

Busy production shops usually need industrial-sized or mid-sized thickness planers, but smaller woodshops and home hobbyists may find that a benchtop planer will handles most jobs that they undertake. More than a half-dozen manufacturers offer benchtop planers that do a uniformly excellent job of surfacing wood yet come in a small package at a relatively small price.

What Counts:

• Machine accuracy

• Dust collection capability

• Ease of setting knives accurately

• Availability of cutter head lock

Sorting out planers

Other than the paint schemes, the machines look very much alike. A benchtop planer is basically a sheet metal box with a movable motor and cutterhead assembly that’s adjusted up and down over a fixed bed by means of a hand crank. Planers in this category are compact and weigh less than 100 lb. — some of them much less — so they can be tucked beneath a workbench when they’re not needed. Maximum cutting capacities are roughly 6 in. in thickness and 12 in. to 13 in. in width. Prices range from about $300 to about $450.

Catch the dust

Planers produce a lot of shavings, so some kind of dust collection is a virtual necessity. Dust collection hoods are often sold as accessories (priced below $50), although a few manufacturers include one for free. Some planers have no available dust hood, which is a disadvantage.

Blade changing varies in difficulty

Some planers use two-sided disposable knives; others have blades that can be resharpened. In either case, changing dull knives is a regular part of machine maintenance. It’s a potentially time-consuming and fussy process that takes anywhere from five minutes to nearly a half-hour. It’s worth comparing the process on a few machines and making that evaluation part of the decision-making process.

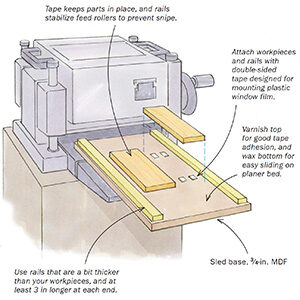

Accuracy is essential

The quality of stock the planer can produce has a lot to do with whether the planer is likely to create an unwanted divot at the beginning or the end of a board (called snipe) and whether the cutting head runs perfectly parallel to the bed. A cutterhead lock, available on many machines, reduces the risk of snipe, while parallelism is a factor of the quality of the tool.

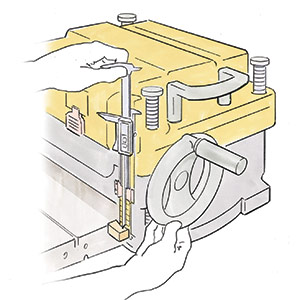

Presets are useful for repeating cuts

The thickness of a cut is adjusted by moving the motor and cutter head assembly up and down, while a gauge reveals the finished dimension. However, some planers have a thickness preset, making it easier to reproduce the same thickness on different batch runs of lumber. After the stop has been set, the cutterhead can’t be lowered any farther.

Log in or create an account to post a comment.

Sign up Log in