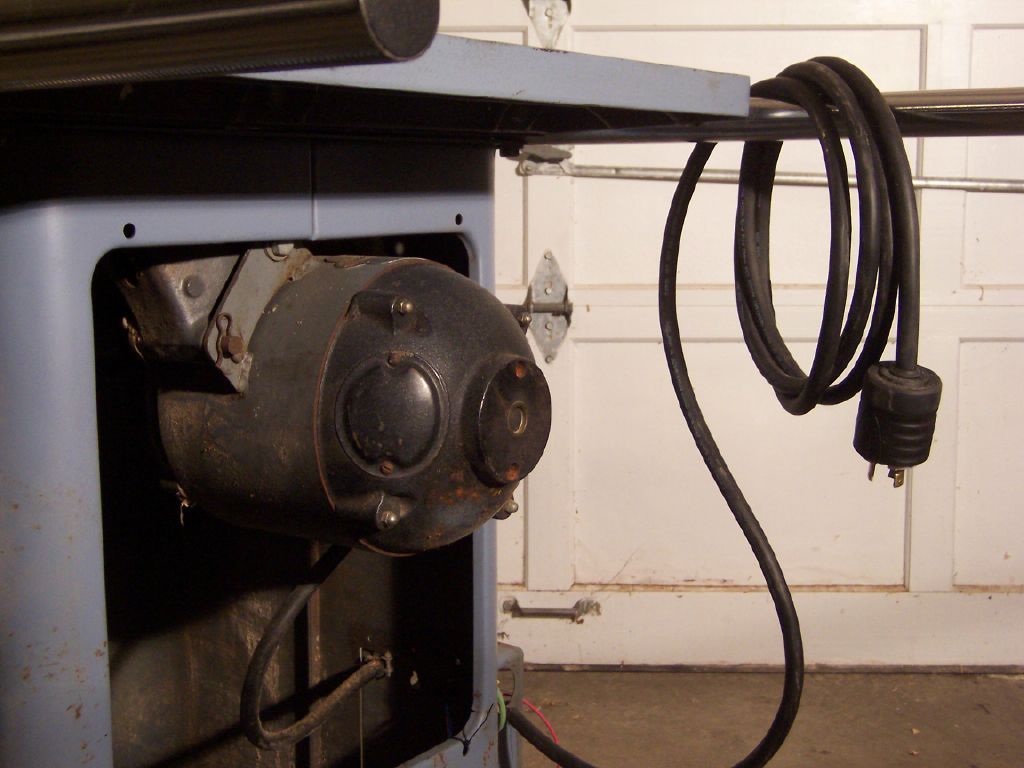

Old, but good. I got this saw for $250. It's heavy, runs great, and cuts like mad. It's not fancy, but it does everything I want.

I like my tablesaw. It’s a 1971 Rockwell Unisaw with an 1 hp repulsion induction motor. Yes, it is a cabinet saw. And no, 1 hp is not underpowered. R/I motors generate tons of torque, and my saw powers through everything. At least it did.

When I bought the saw ($250, I just had to throw out that gloat), it was wired for 120v and had a light switch to turn it off and on. When I could plug it into a dedicated circuit, the saw worked fine. But our move to Connecticut brought me to a garage without a dedicated 120v circuit. That meant the saw was sharing power with lights, outlets, and who knows what else. So, the saw would bog down.

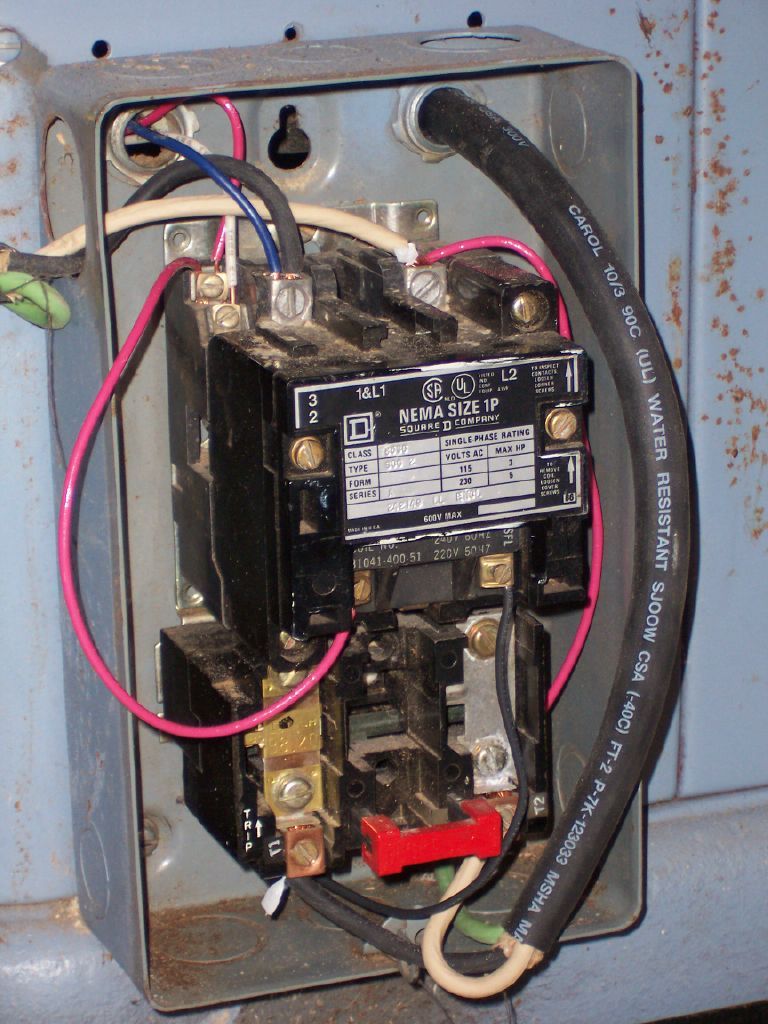

The solution? I installed some 240v circuits and decided to rewire my saw. That turned out to be quite an adventure and learning experience. First, my saw has a magnetic starter. To get ready for 240v, it needed a new coil, a new heater, and to be rewired. Second, I needed to replace the power switch with a two-button control station. Finally, I had to run new cord between the motor and starter, and the outlet and starter.

Well, I had no idea what to do, but some help from the kind folks at Old Woodworking Machines got me on the right track. I found a wiring diagram for my starter, struggled with it for several days, and finally figured it out.

Now that I’m done, the saw runs great and doesn’t bog down. And that’s all I really wanted.

Comments

Matt,

I'm just setting up my shop and have a Rockwell Unisaw from the late 50's. Its been in basement storage for 24 years.

It ran wonderfully when I put into storage. It ran so powerfully that it was a little intimidating! The saw blade rotated so fast the the blade would literally "ring" when is was running with no wood in the blade.

My plan is to get this running again. Put a new fence system on it, hopefully find a way to get a riving knife to fit on it. I will be running this on a dedicated circuit. The motor is a 2HP by Marathon Electric (208-220/440 volts ...3450/2850 RPM ...60/60 cycles)..looks just like the one you have in your 71' Unisaw.

It has minor surface rust...much like your 6" jointer.

needs new belts and the swich replaced for safety reasons...it is the original!

My question is....is this "old iron" worth rehabilitating?

Will the cost benefit be worth it? I am guessing that I will be putting at least $700 to $800 into this saw to get it into the 21st century.

I appreciate your thoughts on this scenario.

Thanks,

ADD2`

ADD2,

I'd be surprised if you spent $700+ rehabbing your saw, even with a new fence. Unless I am missing something in your comment, the most expensive part will be the fence. I guess you could spend in the neighborhood of $400 for a new fence, but there are great after market fences that would cost much less. The other parts shouldn't cost too much.

I should note that you won't be able to find a true riving knife for the saw. The way that the motor and trunnion work prohibits it.

I can't make a decision for you, but I can say that a 1950s era unisaw is one heck of a machine. I would be glad to have one.

Matt,

Thanks for your comments! I will take the plunge... I'm pretty sure this machine has plenty of life in it. I got it out of a department store workshop in Worcester Massachusetts. It was used to make seasonal window and floor displays in the late 50's and 60's and 70's...what I would consider light use.

I'll let you know how it goes. Once I get it done I'll send some before and after pics. I'm new to this site but I'll see if it is possible to send photos.

Thanks again!

ADD2

I have a Rockwell Unisaw that I believe is a 1957 model and wouldn't trade it for any other saw with the possible exception of the new redesigned Unisaw. Just after I purchased my old Unisaw I was wondering whether I should consider installing a newer and bigger motor and discussed that thought with the people a Old Woodworking Machines. They told me that would be a foolish mistake to make and I should keep what I had.

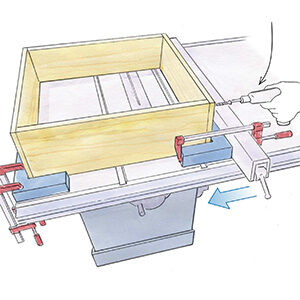

I have upgraded the fence with an Exacta and have also extended the table on the right side. I still have the simple 220 volt switch and would like to change over to a magnetic switch. Thanks for all of the good information!

Log in or create an account to post a comment.

Sign up Log in