Birth of a Lee Valley tool

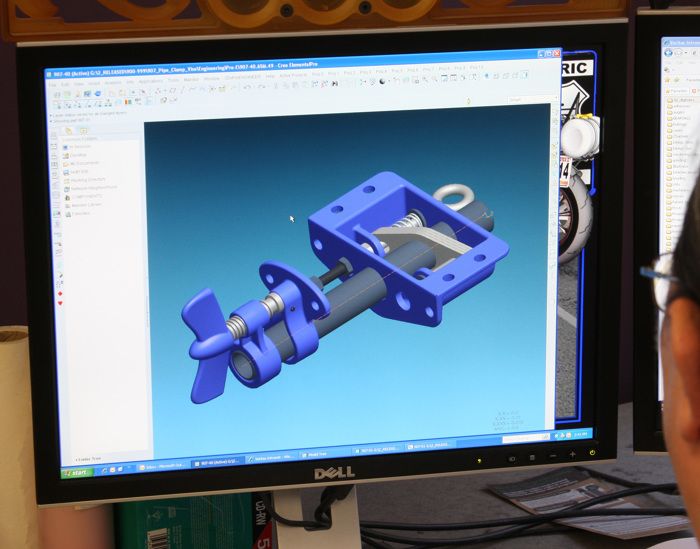

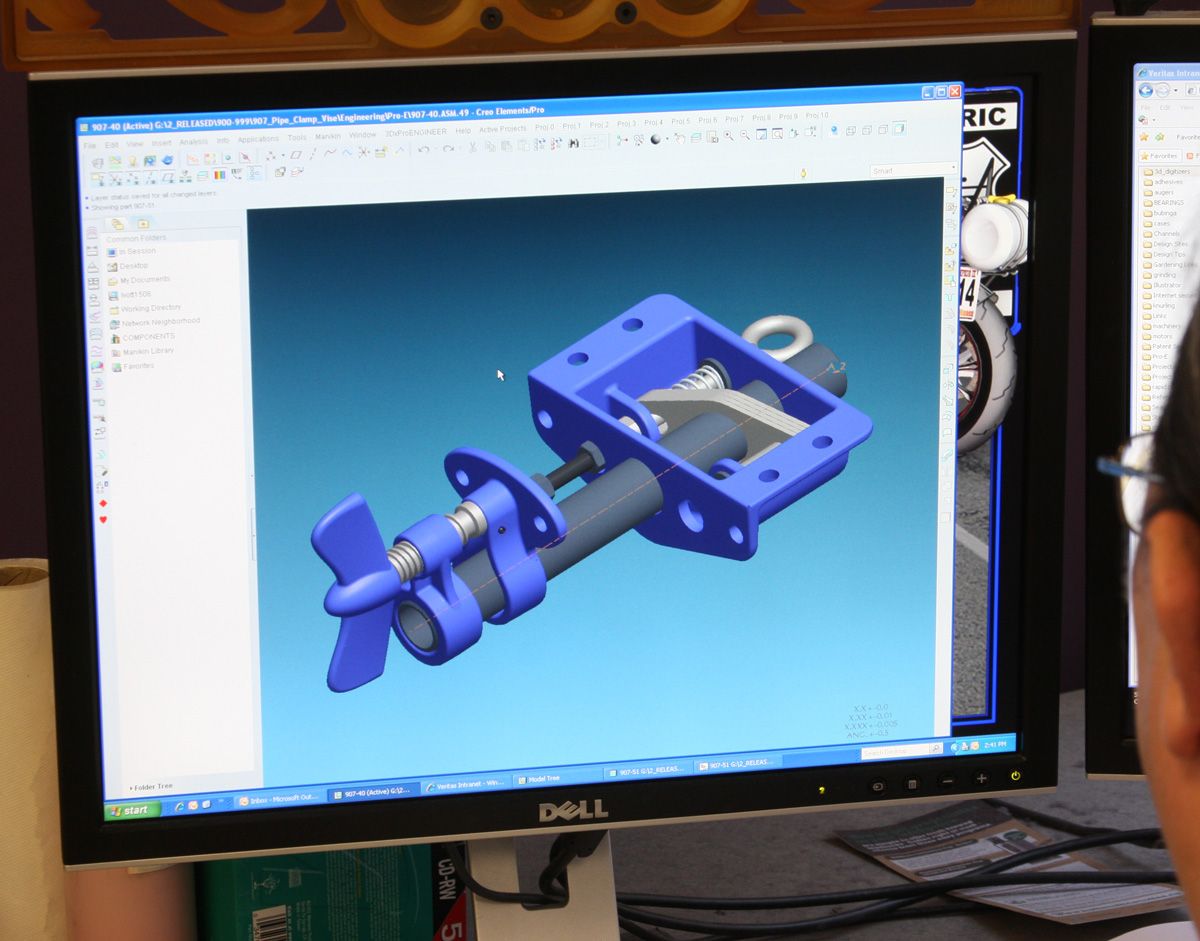

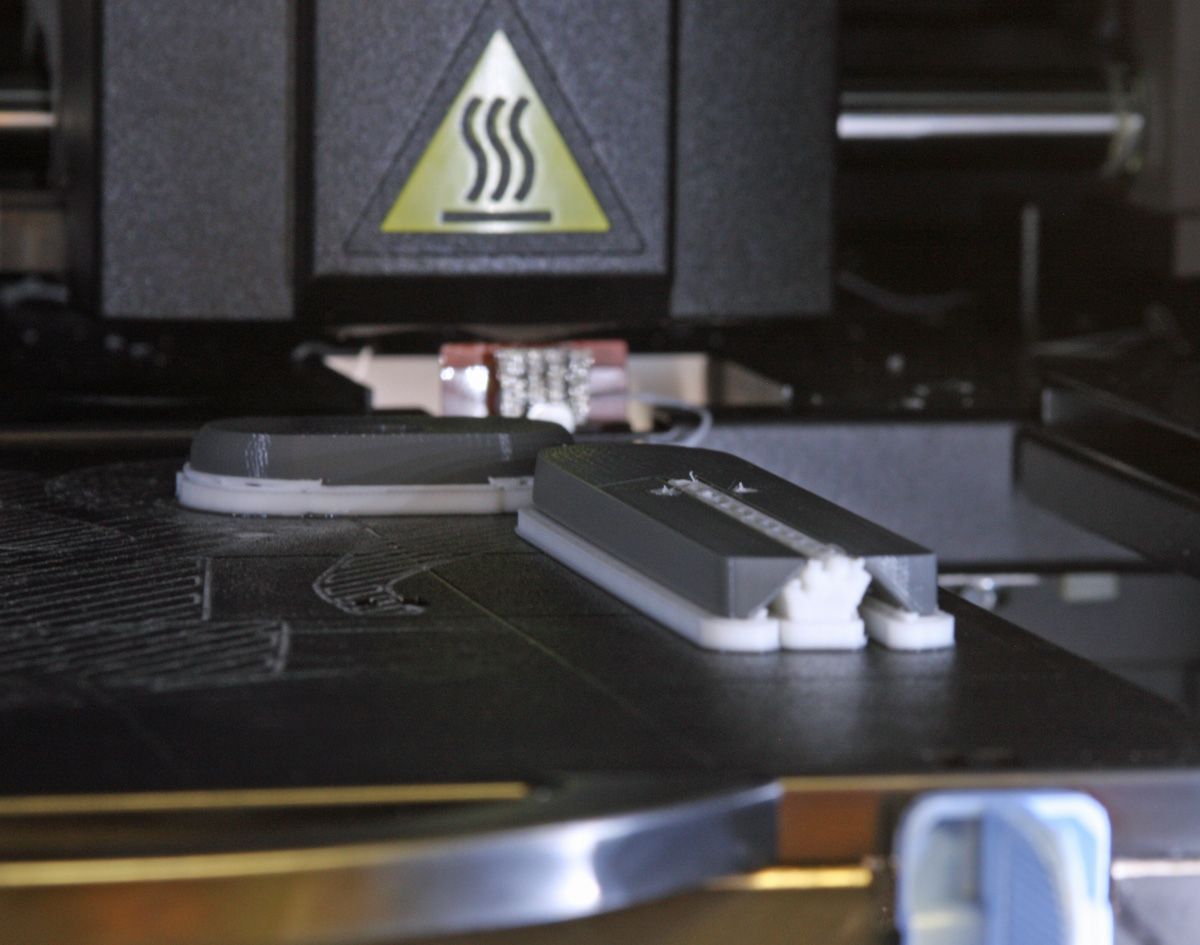

From there Brent had all the info he needed to create the final product in CAD, designing each of its components.

Update October 24, 2012: Be sure to catch our exclusive video tour of Lee Valley Tools’ manufacturing operation in Ottawa, Ontario.

On the occasion of Lee Valley Tools‘ 35th anniversary, Jon Binzen and I recently visited the company’s headquarters in Ottawa. It was a inspiring and fascinating to go behind the scene’s at one of the world’s top hand-tool makers, and we did our best to bring that experience to you. Jon took notes and still photos for an article in the latest issue of FWW, and I grabbed a bunch of extras for FineWoodworking.com: video clips of the manufacturing process, plus two audio interviews for the latest episode of our Shop Talk Live podcast, along with the photos in this blog.

While I was there I met all the product designers, guys I have been wanting to talk to since I first started buying Veritas’ innovative problem-solvers 15 years ago. Just to give two examples, my sharpening process took a quantum leap forward with their grinder tool rest and Mark II honing guide. Both are a boon to modern woodworkers, and both were designed and manufactured in North America, which is a rare thing in itself these days.

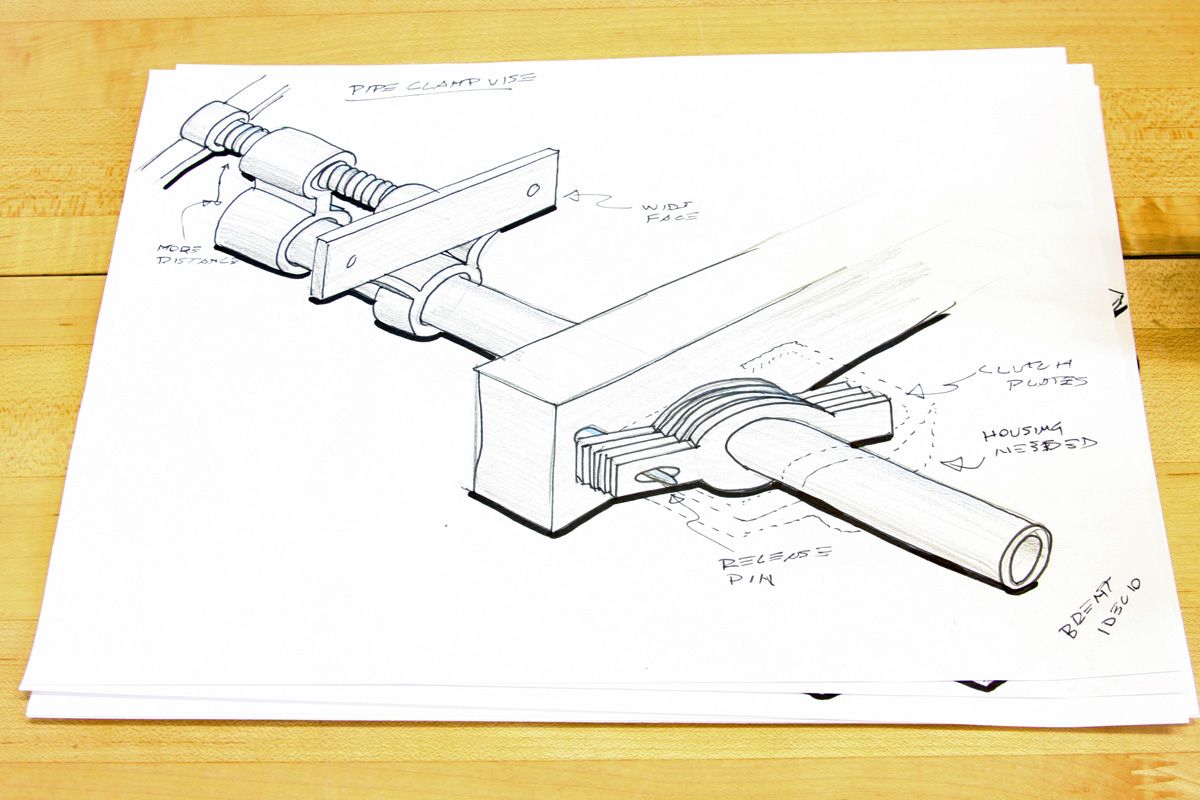

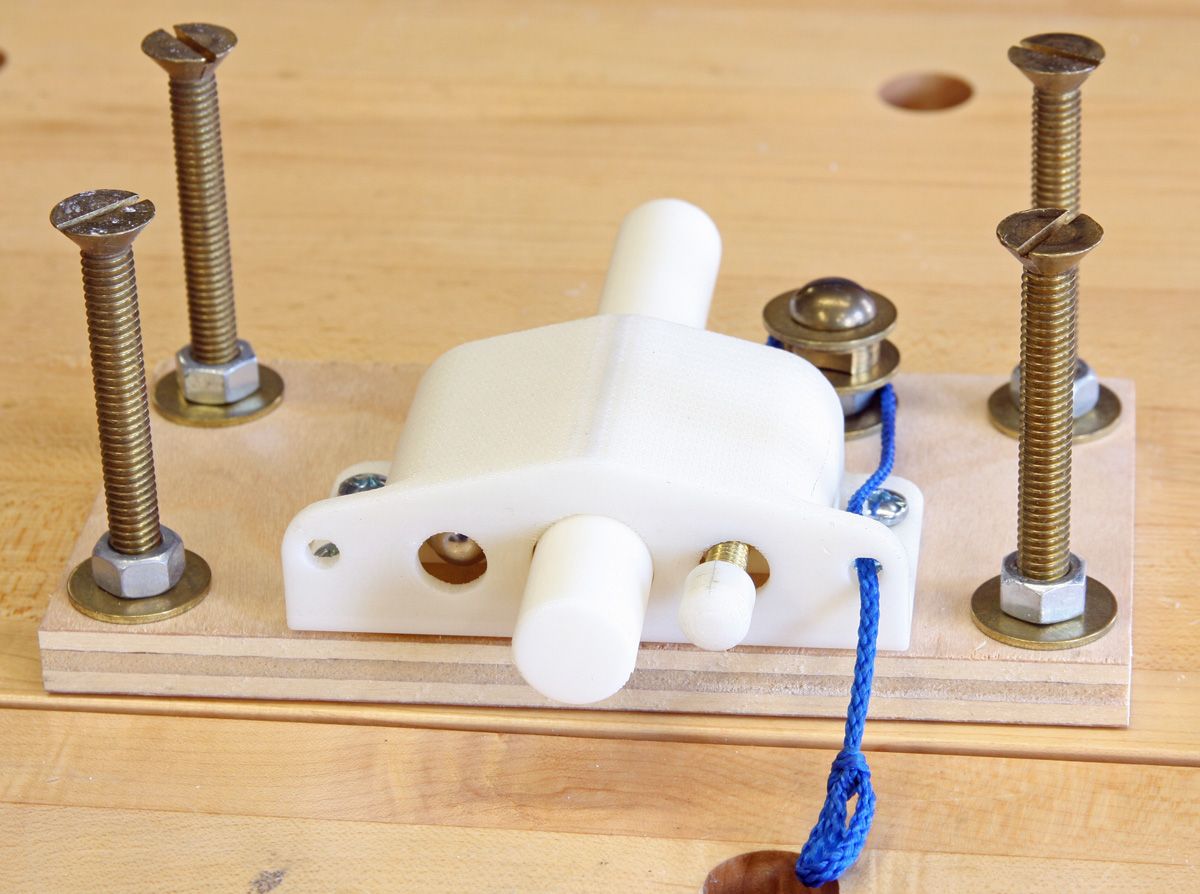

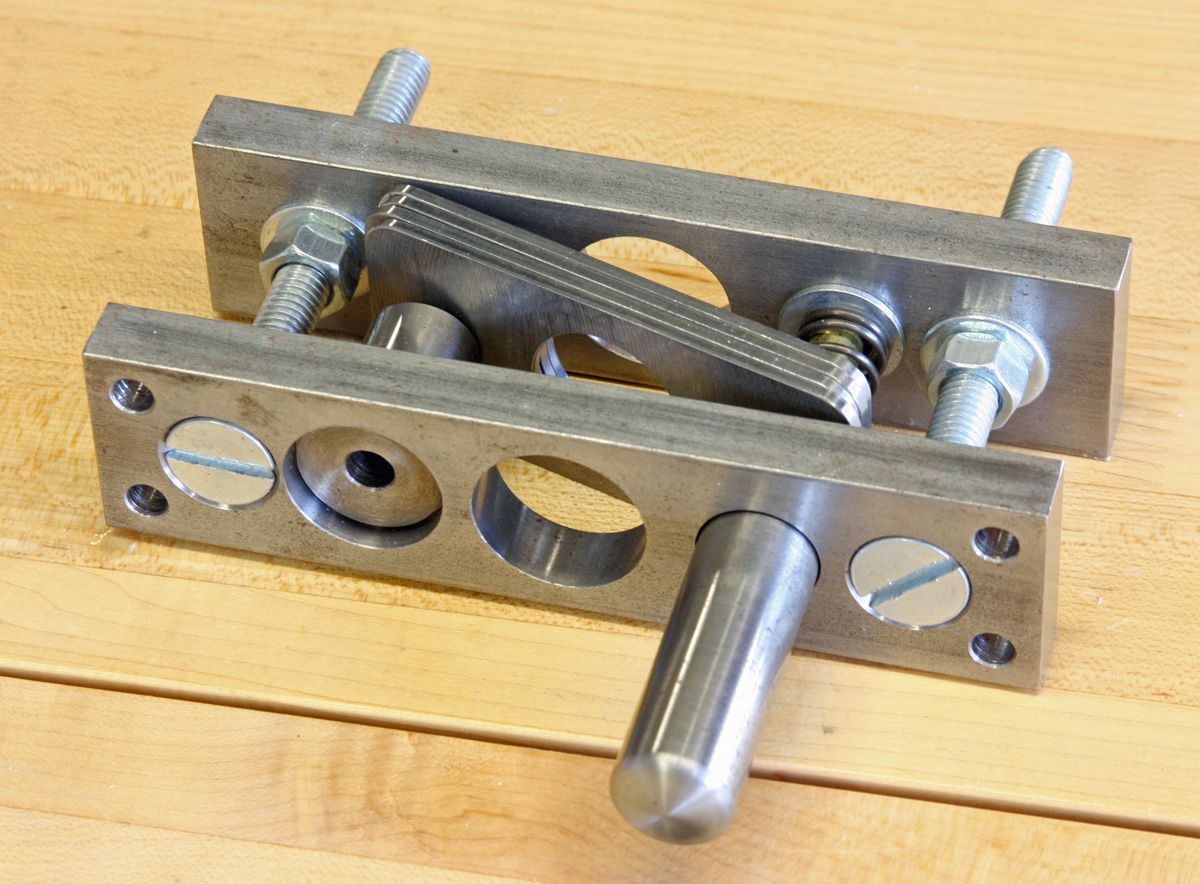

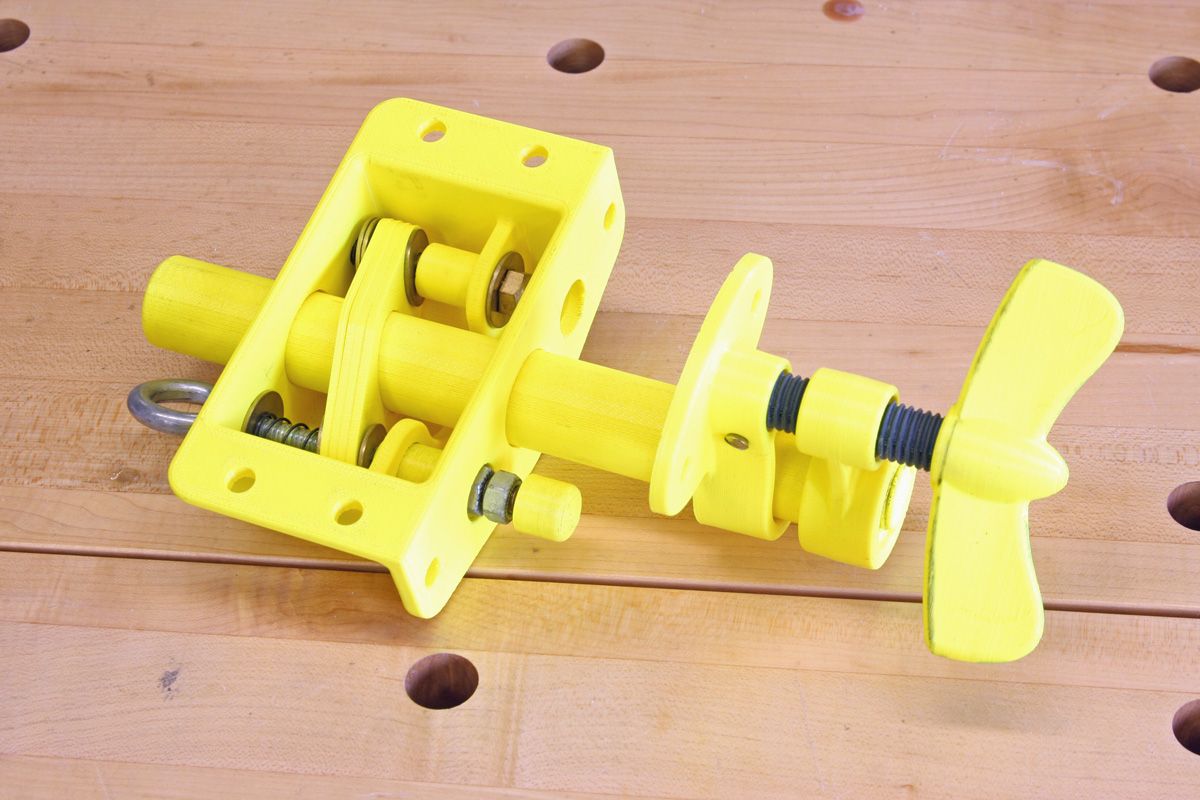

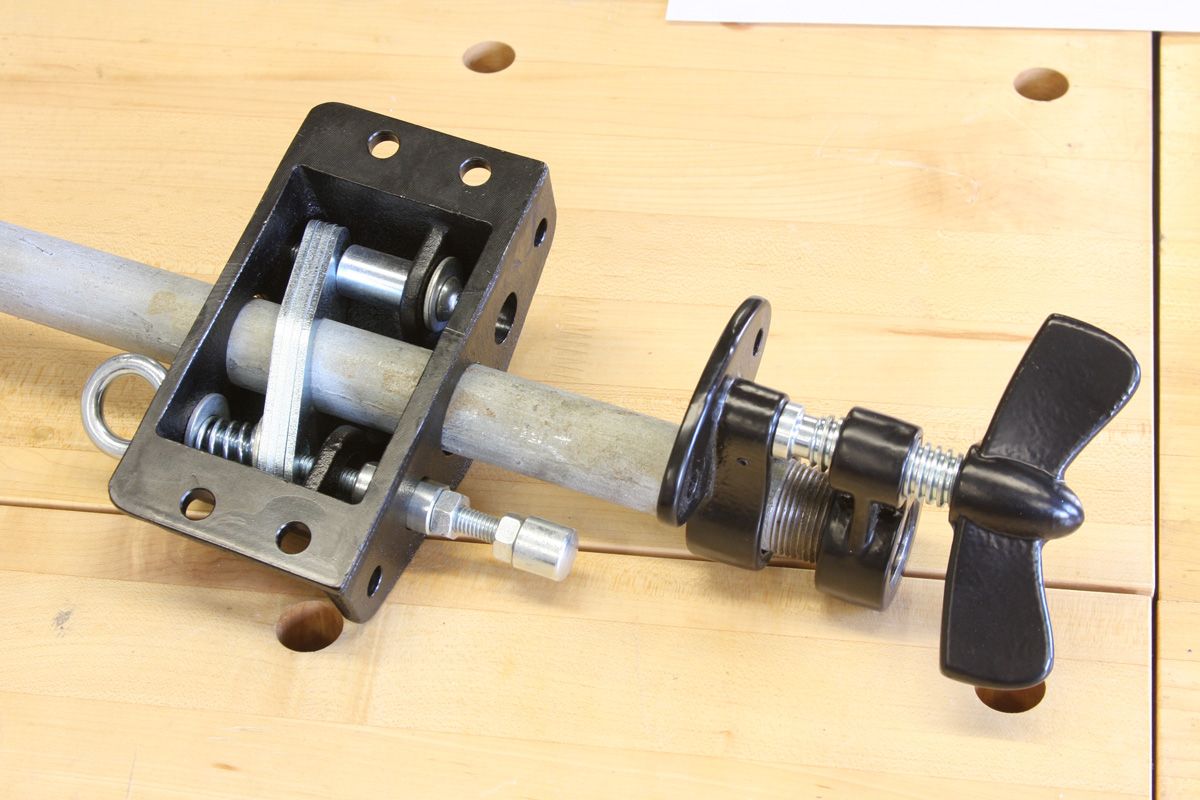

Product designer Brent Hyde took me into the project room, which reminded me of the inventing room in Willie Wonka’s chocolate factory. The whole history of original Lee Valley and Veritas products was there, each with its own box on a shelf, containing all of its prototypes, basically its story. The designers brainstorm together at times, but work independently on their respective assignments. Brent took down the box for the new Lee Valley pipe vise, a product he had brought to life, and laid out the contents.

The stages represent the common process for developing new tools, and demonstrate some of the tools and techniques the designers use along the way.

Comments

Can't wait to see the videos! I listened to the podcast on a long drive and really have me intrigued. I, too, own the MK II honing guide and it's phenomenal.

So glad Robin (Rob) is committed to manufacturing in North America.

Hi

As an avid woodworker for many years I'm always amazed at new ways for tackling woodworking joinery...A jig I discovered awhile back and which I used for all my dovetails in my new kitchen cabinets is called the Kehoe Dovetail jig and is one of the best and easiest to use...It's concept is totally different from all the other dovetail jigs and I'm not sure if Fine woodworking has even tested it yet...(the Leigh is good but not as easy to use)...Keep the new "toys" coming.

Bill Carlson

Interviews were great, would love to see videos but your video frames are truncated in both Firefox and Internet Explorer so I can't access the volume, pause/play buttons, and even the tabs or scroll bars on the right-hand list. Can't find a way to contact webmaster on your site, posted something about this in Knots forum a while back but no replies or improvements. Can't even get to Knots today, link at top of page takes me to finecooking.com error page.

I know this really doesn't belong in a blog comment but there doesn't seem to be a way to contact anyone about a website problem so any help would be appreciated. Email me with a contact addy and I'll send screenshots.

Thanks, love the podcast.

Where is the link to these videos? It looks as if they have been published, because bill71 had access to them. But there is no link from here.

Podcasts are useless for that type of topic. They are good to discuss "philosophy", but when times come to the real stuff, nothing beats a good moving picture. I remember 5 seconds clips that are worth 2 hours of listening in my continuous learning experience as a woodworker.

Thank you Lee senior for starting Lee Valley. We had little access to such tools in Canada and you changed all that and my woodworking.

It is so good to see the firm prosper and grow. It will, so long as it remains relevant to us with good products and service. Their innovations sure are "jazz" and it is good to see them take a hard look at classic designs and improve on them. Along with Lie Neilson, they have done so much for woodworkers and raised hopes that we can continue to manufacture in North America in a viable way. The respect with which both LN and LV make and handle their products makes us woodworkers want to use them with equal respect and they urge and inspire us to do work that is worthy of such tools. Thank you.

Log in or create an account to post a comment.

Sign up Log in