Williamsburg's Kaare Loftheim worked on a reproduction of this "bureau table," type of dressing table popular in Washington's time.

The program kicked off in earnest today with the woodworking presentations. First up was Williamsburg’s own Kaare Loftheim, reproducing a bureau table made in 1754 by Williamsburg cabinetmaker Peter Scott, for Daniel Parke Custis, Martha Washington’s first husband. He worked on the case joinery first, starting with the bottom, which acts as the foundation for the piece, and then joining the vertical case parts to it.

He cut dadoes in the interior case sides, the ones that go on each side of the center door, using a dado plane from Old Street Tool, formerly Clark and Williams. He talked about setup first, explaining how important it is to get the blade aligned with the nickers, so there is no tearout. The joinery was complex, a mix of dadoes, tenons, tongues, and dovetails, and it was great to see everything come together under a few hard mallet blows. “There is a fine line between a dry fit and a split,” he said. “If you are a good furniture maker, you are a good repairman.” Big laughs from the crowd.

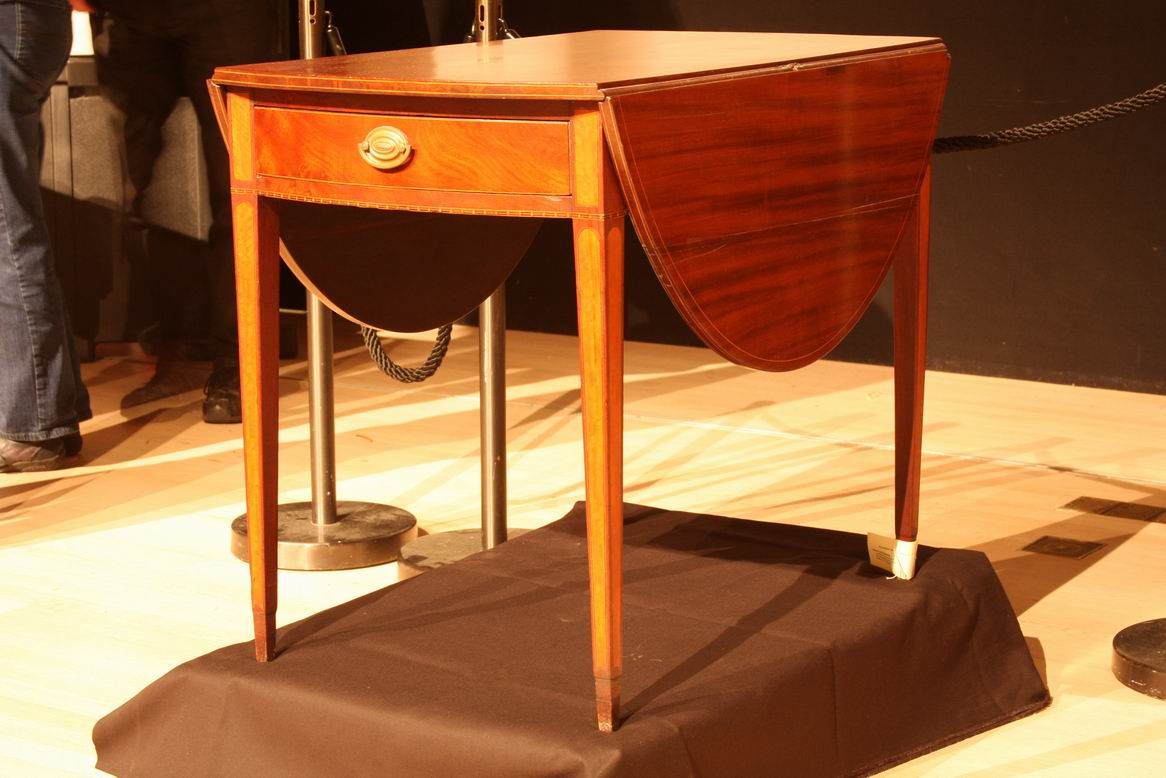

Then Dan Faia and Matt Wajda, both teachers at North Bennet Street School, took over, building an inlaid Pembroke, or breakfast, table from the slightly later Federal period. These tables were very popular at the time, and the Washingtons would have taken their tea on one of these on their piazza at Mount Vernon. Dan started by making a knuckle joint, used on all types of swinging legs and other table leaf supports in period tables. The squareness of the joint is critical, as you don’t want to swinging part (fly rail) to rise up or drop when it pivots outward. As usual, it all starts with square stock and precise layout.

One of Dan’s great tips was setting your knife into a tick mark first, and then bringing the square up to it to draw or scribe an accurate line, instead of trying to place the square first against the mark.

Each side of the knuckle has 45-degree notches that act as stops. To form these with hand tools, Dan made a saw-cut to mark the center of the notch, and then used a ramp block to guide a wide chisel as he cut in from the sides. He said many people use a shoulder plane on its own to do the job, but he prefers the guidance of the ramp block, and the shoulder plane will cut into it. He did use his shoulder plane to cut the other side of the notch, though, resting its side on the ramp block. Love those guide blocks for hand-tool work.

Much more went on throughout the day, of course; but you’ll have to attend the event someday to get the full experience!

Log in or create an account to post a comment.

Sign up Log in