This “weekend workbench” is solid, inexpensive, and easy-to-build

by Bob Van Dyke

A workbench with an end vise and front vise is easily the most important tool in your shop, one that you use on every project. If you don’t already have one, or if yours is old and rickety, it’s time to upgrade.

You could just buy a bench – there are some very good ones out there – but you could easily spend $1,000 and not improve on the bench that I’ll show you how to build in this article for around $300.

This bench is everything a good workbench should be: It is heavy and strong, so it won’t skate or wobble. It has a flat surface big enough to support a medium case side or tabletop. And it’s capable of holding your work securely, with an end vise that can be used with benchdogs to hold work flat or like a front vise to clamp work upright. Best of all, you can make this bench in a weekend, to your own dimensions, and you don’t need a ton of tools.

If you’re wondering whether a bench like this can really do the job, I have more than 25 of these benches in my school and they are still going strong after 11 years and 3,500 students. click to enlarge diagram

Easy Dadoes on the TablesawYou don’t need a dado set to cut the joints on this bench. Here’s how to do it with your standard blade and miter gauge.

The rip fence will be your stop. Lay out one of the legs and set the fence so the blade lines up with one end of the dado. click to enlarge |

Then the fence stays put. Use a spacer block to reposition the leg for cutting the opposite end of the dado. click to enlarge |

Cut each wall cleanly, supporting the leg with the miter gauge. Now make passes to remove the material between the two walls. click to enlarge |

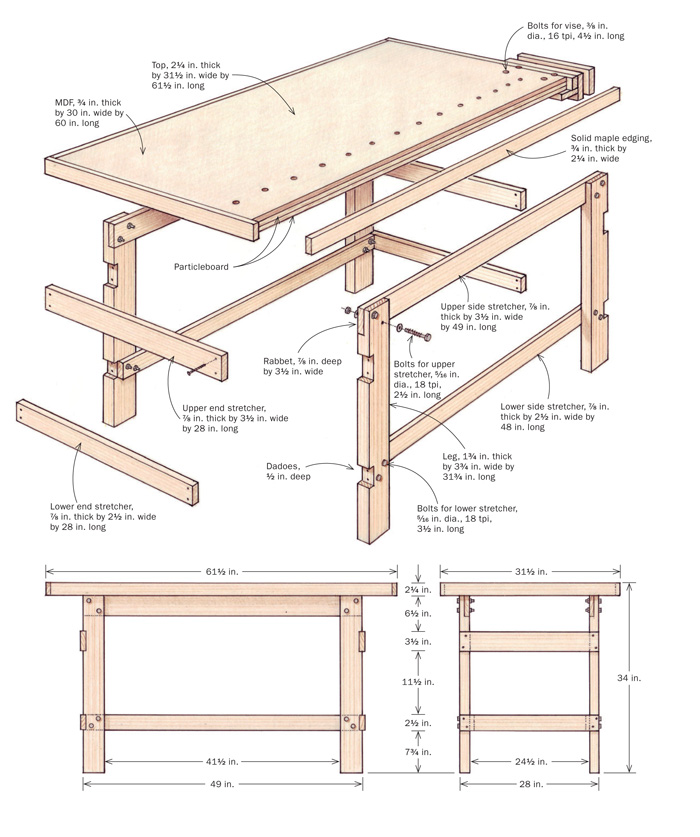

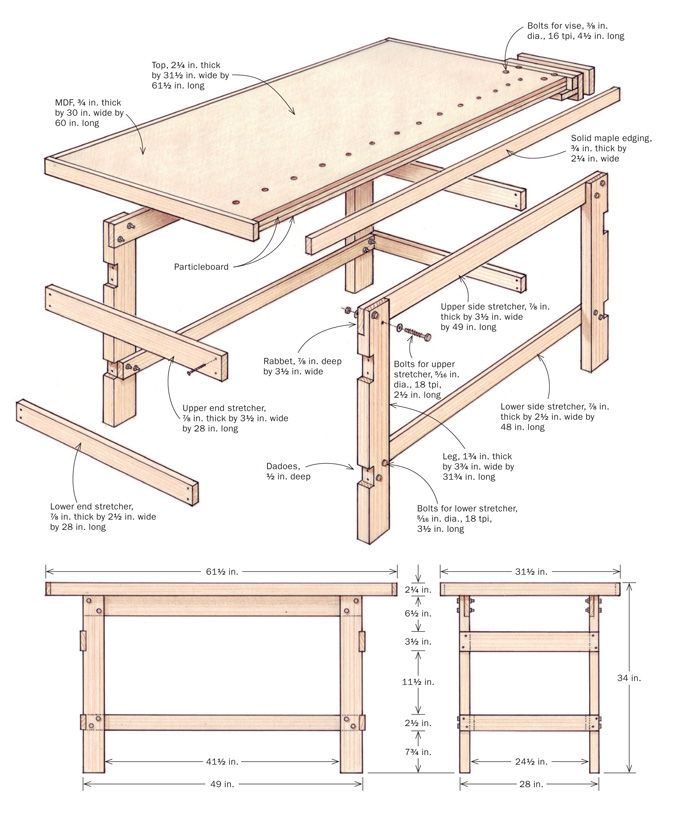

Simple joinery and fasteners make a sturdy base

I like to make the base from ash, maple, poplar, or oak. The base consists of two end assemblies, each built from a pair of crosspieces dadoed into the legs. These end assemblies are connected by two long stretchers bolted in place on each side. The top long stretchers are rabbeted into the tops of the legs.

Glue and screw the ends. Drill pilot holes and countersink for the screws while the assembly is dry-fit. click to enlarge |

All of this joinery is best cut on the tablesaw with a dado set but it’s also possible, if more tedious, to do the work with a standard blade and a miter gauge. Either way, a single fence setting and a spacer block is used to cut each corresponding joint exactly the same width and in exactly the same place on each leg. If you leave the crosspieces and stretchers a bit wide, you can edge-plane them in the thickness planer for a precise fit in the dadoes and rabbets.

With the joinery cut, begin construction of the base with the two end assemblies. Before starting, break all the edges with a chamfer or roundover. Check for square during glue-up by measuring diagonally across the asssembly in each direction. Adjust at the corners if needed until the measurements match.

Connect the end assemblies. The long stretchers are through-bolted for easy disassembly. click to enlarge |

The rest of the assembly consists of connecting the two ends by attaching the long stretchers. Set the base upside down on a level work surface and clamp the stretchers in place while drilling the bolt holes. With the base assembled, you can turn it over and use it to build the top.

[[[PAGE]]]

The top: A triple-decker sandwich

Cutting 4×8 sheets of medium-density fiberboard (MDF) and particleboard by yourself is no picnic. Buy one sheet of each and have your supplier rough them down so each piece is 1-in. bigger than the final size in each direction. You can use the particleboard offcuts to piece together the top’s middle layer. If you plan your cuts carefully, the middle layer will consist of two pieces with only one seam.

Before assembly, use a tablesaw or a router and straightedge to cut the top layer accurately to final size. Cut the other layers about 1/4-in. to 3/8-in. bigger than this layer.

Start the glue-up with the top layer facedown on the base. Roll yellow glue onto the surface, then place the pieces of the middle layer on the waiting piece. Make sure you don’t drive any screws where you plan to drill dog holes. Afterward, use a router and a flush-trimming bit to bring the middle layer flush with the top. Finish the glue-up by repeating the entire process to attach the bottom layer.

The top goes together in layers

Assemble the top. Start with one layer cut to exact size. click to enlarge |

Assemble the top. Use a router and flush-trimming bit to trim the adjacent layers. click to enlarge |

Cut the stock for the solid-wood edging no more than 1/8-in. wider than the thickness of the top, with each piece about 1-in. longer than its finished length. When gluing the edging to the sides, use thick clamping cauls to distribute the pressure evenly. After gluing the edging in place (long sides first) and trimming the ends, use a router to flush-trim the protruding edging to the core–top and bottom. Then switch bits and round over all the edges. Now is also a good time to sand the benchtop.

Add the edging

Use a shim to offset the biscuit joiner when cutting the slots in the top’s edge. This ensures the edging will stand proud of the top for trimming. click to enlarge |

Next, Van Dyke applies the edginig using glue. The long sides are attached first. Clamps and cauls hold them in place. click to enlarge |

A simple overhanging base allows a straight cutting bit to trim the edging flush with the surface of the top. There’s no need to set the top on-edge click to enlarge |

A single vise does double duty

This bench has one vise, which acts as both a front vise and an end vise. You can use it to hold your work vertically for any sawing or chiseling task, or you can use it in conjunction with benchdogs to easily hold a board flat on the benchtop.

Before installing the vise, I use an inexpensive 3/4-in. spade bit to drill a row of holes in the top for the benchdogs. I start the row 5-in. from the vise end of the bench and space them about 4-in. apart, but the spacing can vary according to your needs. What is important is that the holes line up with the dog in the vise.

When you attach the vise, add a spacer block to keep the jaws even with the tabletop. click to enlarge |

To mount the vise, first make a spacer to fit between the vise and the bottom of the benchtop. It should be slightly longer and wider than the vise’s footprint, and thick enough to drop the cast iron jaws about 1/2-in. below the top. Hardwood jaw pads go on before installation, then get planed flush with the benchtop.

Glue and screw the block to the underside of the bench and then clamp the vise in its final position. Mark the location of the vise bolt holes on the bottom of the bench, then use an adjustable square to transfer the locations to the top.

Drilling from the top, start with a Forstner bit to counterbore each hole deep enough to fully recess the bolt head and washer. Use the center dimple left by the bit to drill the through-holes, and bolt the vise in place.

The last thing to do is attach the top to the base. I use six small angle irons available from any hardware store and screw them in (turn the bench upside down).

For a tough, water-resistant finish, I use four coats of Minwax High Gloss Polyurethane on the top and bottom. The finish is exceptionally durable, and can be renewed easily by scuff-sanding with 220-grit sandpaper and brushing on a new coat.

Comments

Another top option might be to use 3 layers of 3/4" Baltic birch plywood. It comes in 5-0 x 2-6 size as a cut size, and so can be loaded into almost any car. You could probably skip banding the edge using the plywood. Yes it is more expensive, but so are the pills for curing a strained back from hauling 4 x 8 sheets of MDF to say nothing of the delivery charge from a lumber yard.

There are many ways to do things. I appreciate the simple direct, low cost approach for building a bench. Thank you for the well done article.

Peter

How is the top attached to the base or did I miss that part???

Log in or create an account to post a comment.

Sign up Log in