The Follow Me Tool has been one of the most reliable and effective tools in my design of furniture in SketchUp. After all, I like furniture with turnings and moldings so Follow Me has been frequently used with successful results. So I was surprised recently to run into some difficulty with the tool.

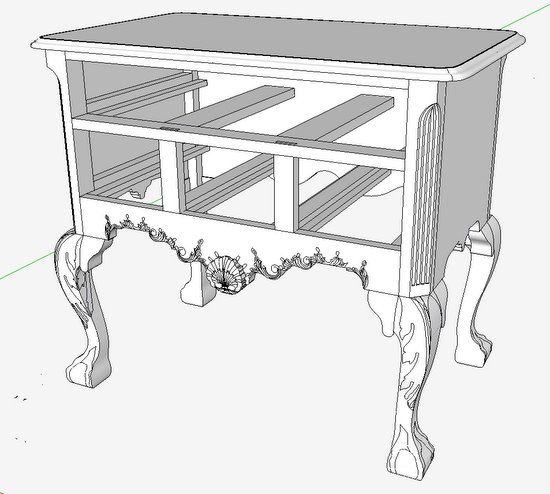

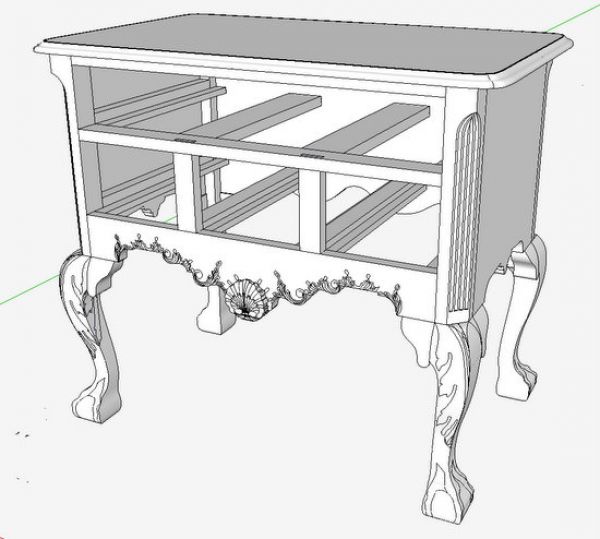

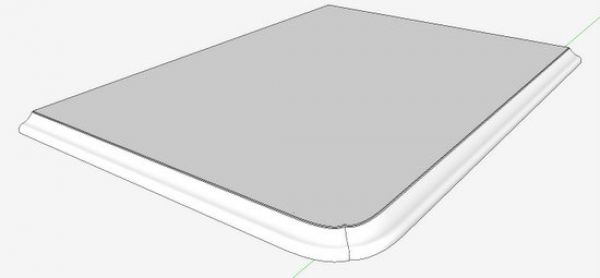

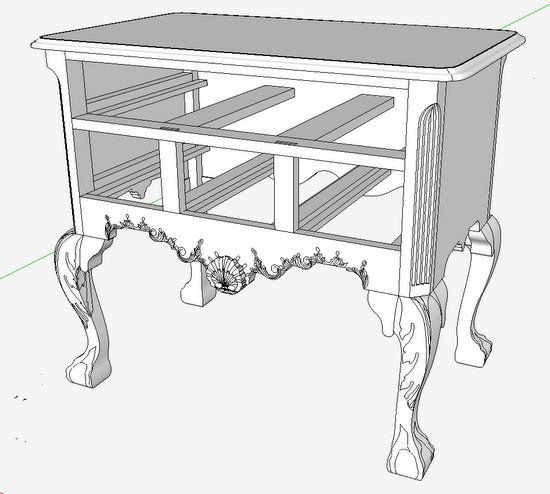

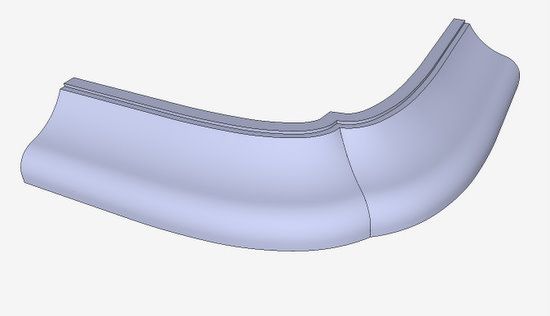

I ran into the problem while working on this Philadelphia Lowboy. The Top has a molded edge, but note the unique curved corners in the front.

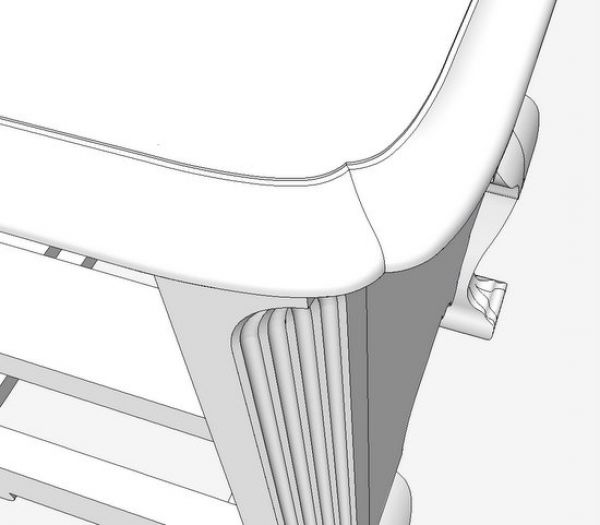

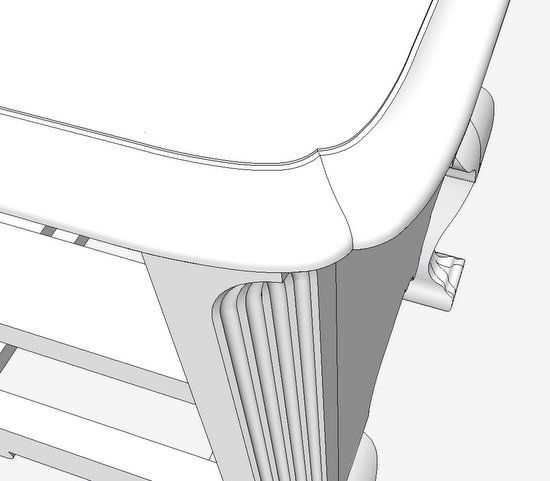

Here is a close-up view of the front corner of the Top. I wasn’t expecting any difficulty making this shaped edge, so it was quite a shock to see funny results with Follow Me. This set me back several hours as I began to experiment with alternative ways of using Follow Me. I knew that it could be done with a plug-in, but I was stuck on making Follow Me work.

The following are some of the steps I used to finally achieve an acceptable result.

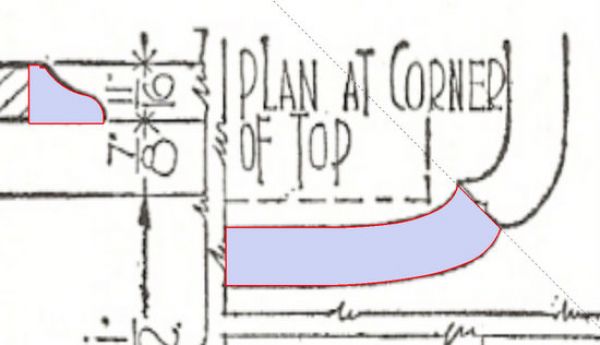

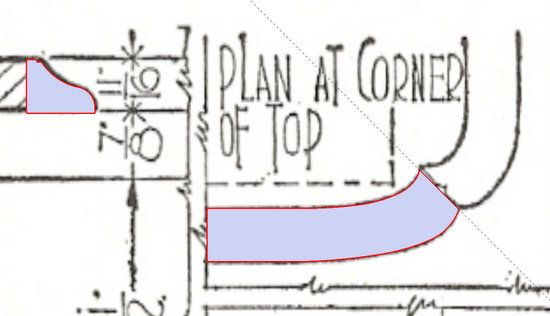

Step 1: Here is a plan view of the Table Top corner along with the profile shape. Using the Arc Tool, I drew over the top of the shape shown with red edges and blue face. The angle at the corner is of course 45 degrees, so I placed an angled guideline with the Protractor.

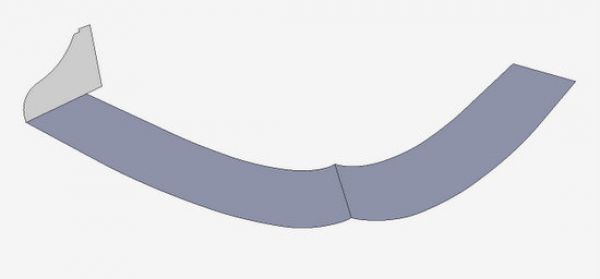

Step 2: Expecting some difficulty with small facets, I scaled up the size of the corner shapes by a factor of 10. Then I placed the profile shape onto the flat shape as shown below. I selected the Follow Me Tool, clicked on the profile shape, and began to drag my mouse along the front edge.

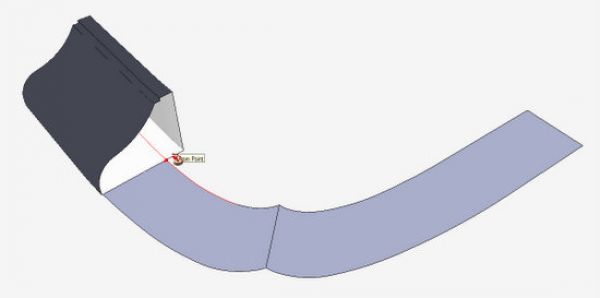

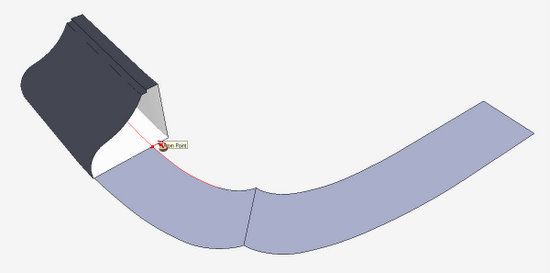

Step 3: Here I am dragging the mouse along the front edge and watching the profile shape extrude the molding step-by-step. Of course, you can operate the Follow Me Tool differently by selecting the path, then clicking on the profile shape. But in this method, it is more difficult to see how Follow Me works and how the profile moves with respect to the path. Note that the profile always positions itself perpendicular to the path.

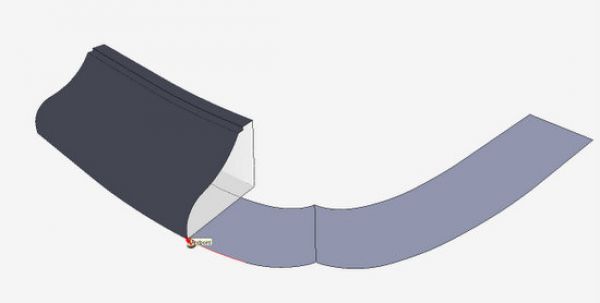

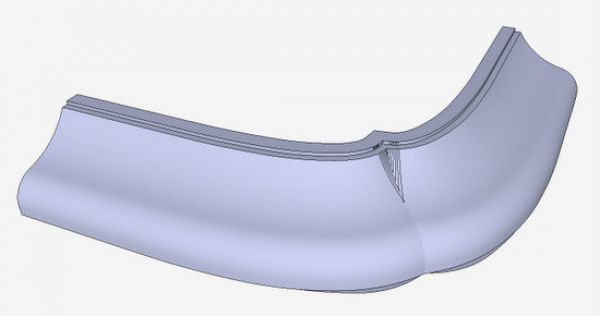

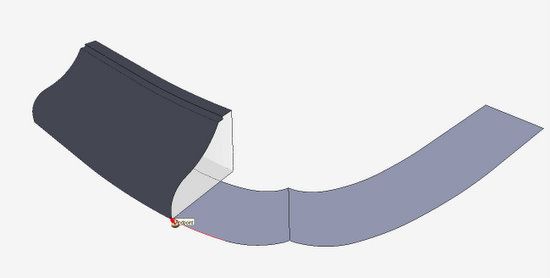

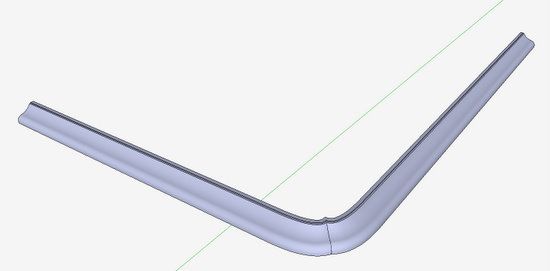

Step 4: Here I’ve completed the Follow Me along the entire front edge across the corner. And you can readily see the problems at the corner. This is caused by the path turning in at the corner so that the profile rotates back on itself.

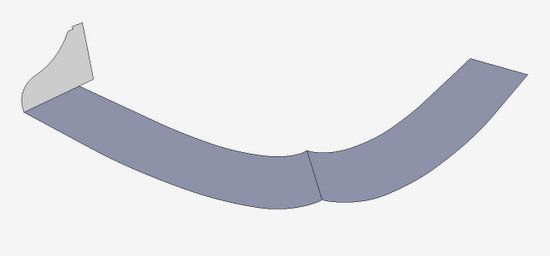

Step 5: Next I restarted the Follow Me, but this time I used the back edge as the path.

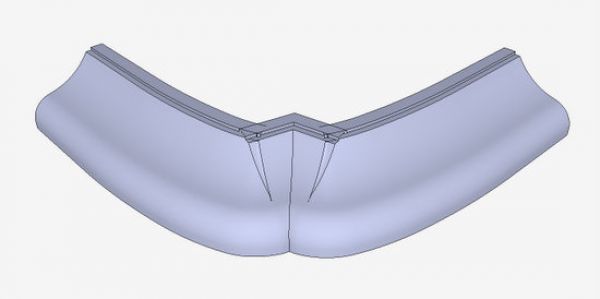

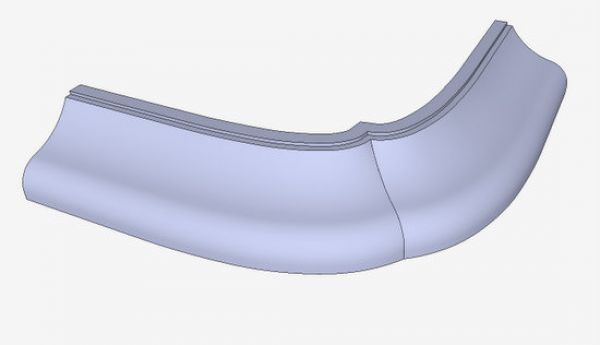

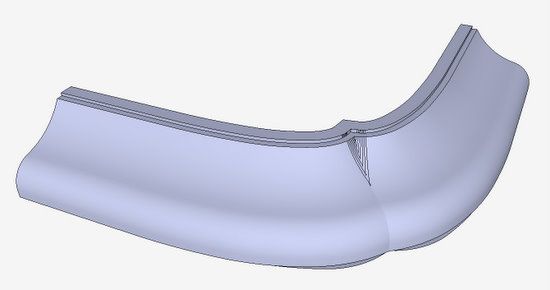

Step 6: Even though there were again problems at the corner, I could see a smooth and proper curved face through the corner. The extra edges were a result of face geometry created within the envelop of the molding shape. So I set out to edit and clean-up this area of the corner.

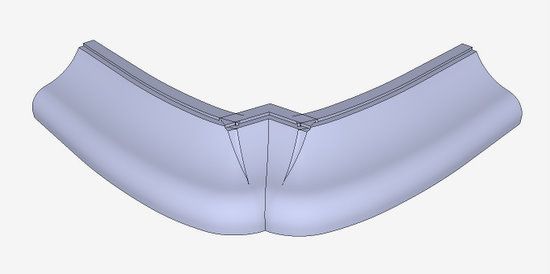

Step 7: I created a cutting plane at the 45 degree angle. Then I selected all geometry and executed Intersect Selected. After cleaning up with the Eraser, here are the results.

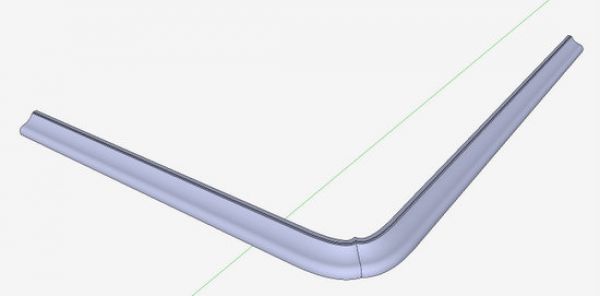

Step 8: Using the Push/Pull Tool, I extended the straight portions of the molded edge.

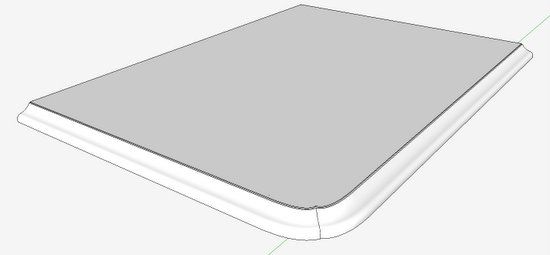

Step 9: I created one-half of the Top by closing in the top and bottom faces. Then I copied and flipped this half to make the whole Top piece.

I suspect there are easier ways to accomplish this difficult shaping (with Plug-ins), but now I know it can acceptably be done using Follow Me only.

Comments

I'm having a similar problem with Follow Me with what seems to be a pretty straightforward application.

What's with the "scaling" up, following, and shrinking? How will that help?

Nice looking model by the way!

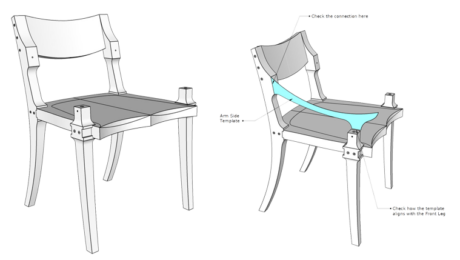

My approach to dealing with Follow Me in cases like this is to split it into sections and do them individually. Then put them together. In a case like this I would divide the path into two at the corner. I would extend the paths beyond where where the miter occurs in the same way I showed for the stopped, curved chamfers on the hayrake table. Then I would run the same profile on both paths, trim each of them with intersecting cutting planes set to the miter angle and move the two together. The final step would involve deleting the coplanar edges on the bottom. If the front and side are identical, all of this work gets done once, a copy is made which is rotated and flipped to create the other part. You can see the progression here: http://flic.kr/p/9MbeWd

As to the scaling up, this avoids the small face issue that can occur which results in holes in the surface. Once the faces are filled, scaling down doesn't result in gaps.

Dave

Log in or create an account to post a comment.

Sign up Log in