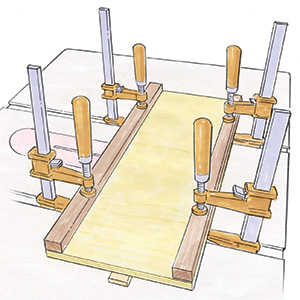

Most woodworkers are underclamping their joints. Use these three keys for clamping success: match the clamping pressure to the wood, make sure that you have enough clamps, and distribute the pressure effectively.

Nothing provokes more stress than a big glue-up. Learning how to properly clamp your work is one of the most critical elements of success. But this raises the question… how much clamping pressure is enough?

To answer the question, Fine Woodworking found Roman Rabiej, a professor in Michigan, who revealed some of the secrets to effective clamping in an archive article. Over the years, he’s done many scientific studies on glue joints, studying glue types, clamping pressure, wood species, etc.

In reality, Rabiej found that most woodworkers are underclamping their joints. While some woodworkers fear over-clamping could starve joints of glue–it’s a myth. You can almost never apply too much force using common woodworking clamps, Rabiej says.

To help hobby and professional woodworkers, the professor came up with three keys to clamping success that answers the following questions: What is the optimum force when clamping soft and hard woods? How many clamps should you use and how should you arrange them? And last, how can you test a sample joint to see if you are getting good results?

Success with Clamps: 3 Keys

1. Match the clamping pressure to the wood

2. Make sure that you have enough clamps

3. Distribute the pressure effectively

If you’re not Arnold Schwarzenegger, you may have a little trouble applying as much force as Rabiej recommends, however he gives some good guidelines to try and live up to. This should help relieve your fears about overclamping.

What about you… what clamping tricks and techniques have you developed over the years to help you assure a successful glue-up?

Comments

By these calculations, one cannot apply too much pressure to most woods. A 2" x 48" glue up would require 24 pipe clamps and 65 parallel jaw clamps. If you are using 4/4 stock, the numbers are cut in half. But that is still a lot of clamps. You would almost double those numbers for oak, and triple them for hard maple. I guess it is almost impossible to over clamp a project!

In the above post, the first calculation was using cherry, which requires the least pressure.

I guess you could say that my success in glue ups can be chalked up to dumb luck. From what I just learned I haven't been using enough clamps, the right kind of clamps, or enough pressure. Great information!

I see galvanized pipe clamps in use here. It's impossible to generate high clamping pressure with these because the galvanized surface is soft and the clamps slip. All pipe clamps should be black iron.

Log in or create an account to post a comment.

Sign up Log in