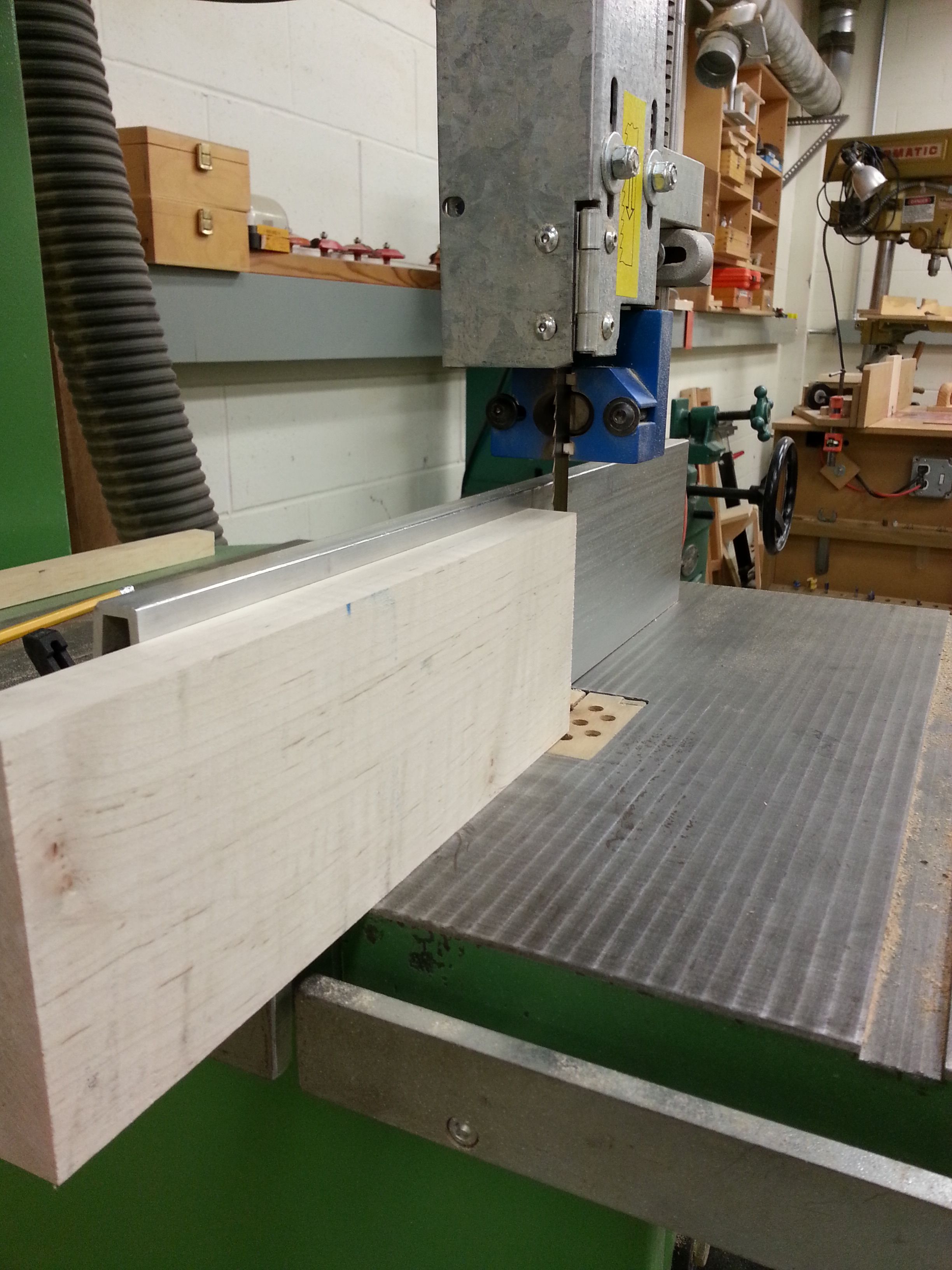

The piece that would become the sides of the box, found in the cut-off bin.

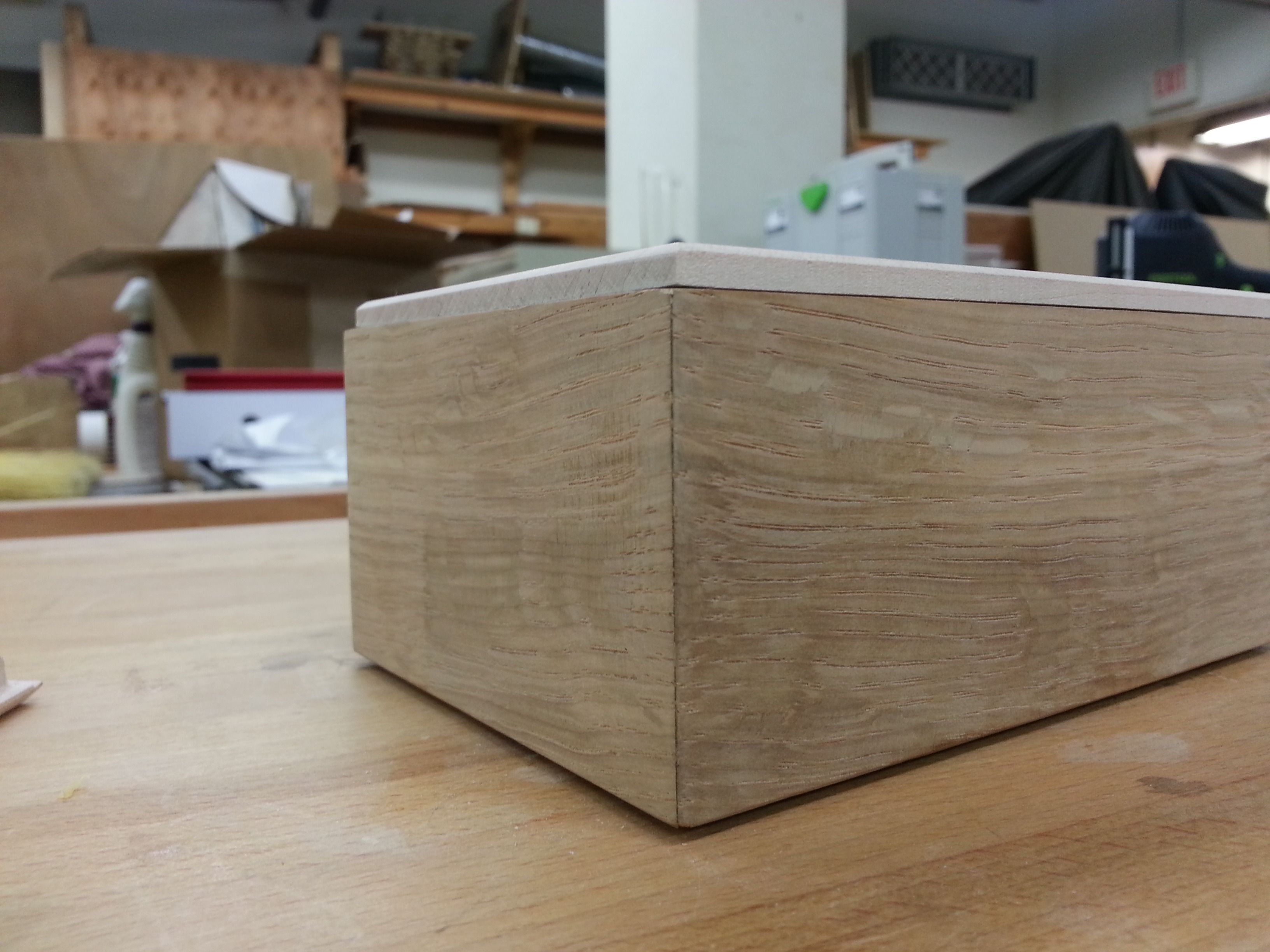

I recently set about building my first box while their was space and time available in the shop here at Fine Woodworking. I decided on a simple miter box to test out Matt Kenney’s grain-matched, four-corner miter technique and also to give myself some more experience cutting joints, rabbets and grooves on the table.

As an avid mechanic, I’ve had very little chance to work with wood outside of my days as an apprentice in my father’s business as a framer/roofer. Even that experience did not include any type of furniture or truely fine woodworking.

The materials were all cut-offs or scraps I found around the Fine Woodworking shop. The sides are white oak and the top and bottom are maple. The box is roughly 5 1/2 in. wide, 2 in. tall and 3 1/2 in. deep.

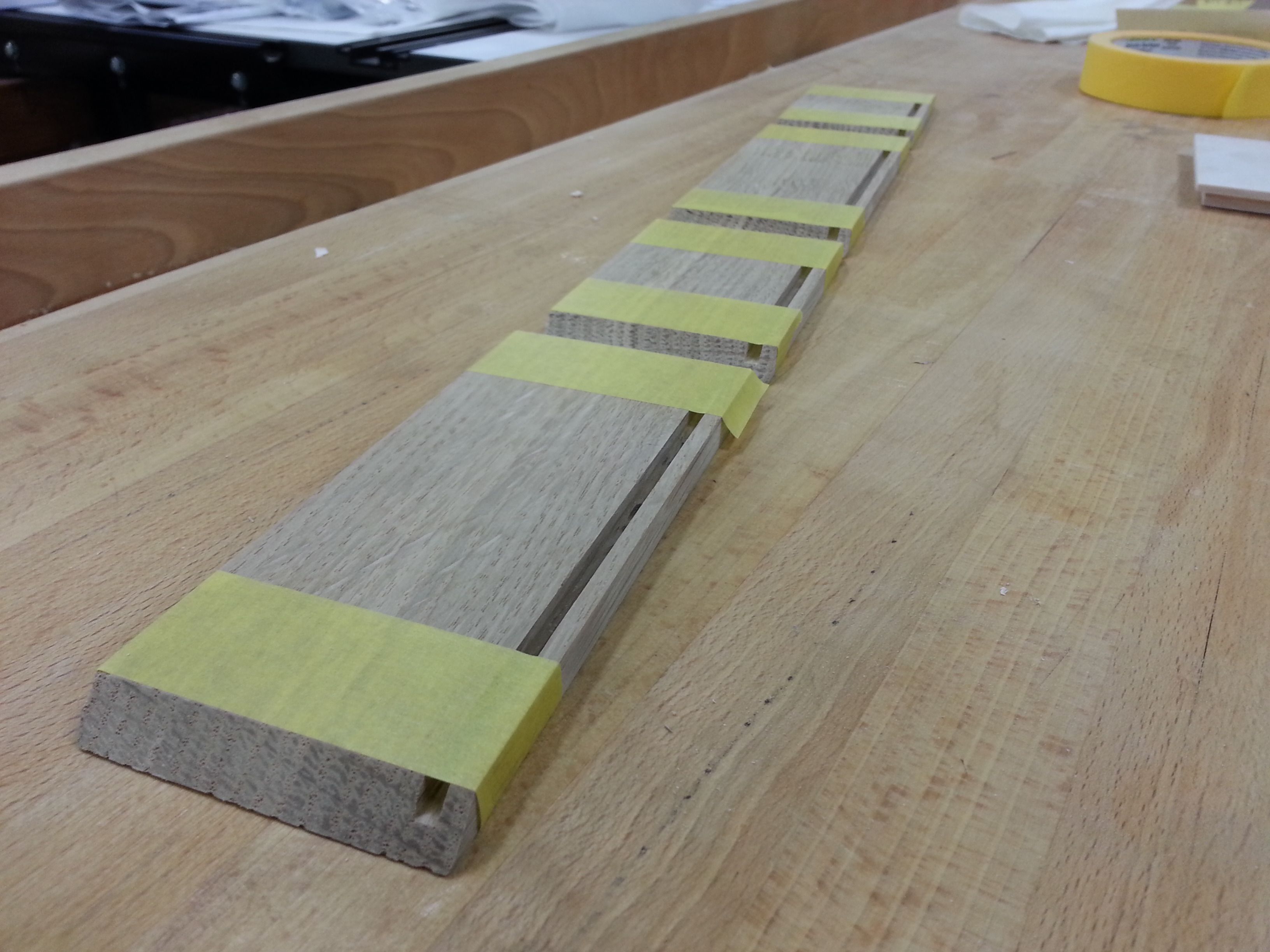

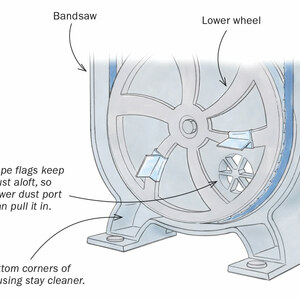

All rabbets, grooves, and miters were cut on the table saw. This proved to be the hardest part of the build. Even with the awesome SawStop tablesaw in the shop, adjusting the sled and blade perfectly required micro shimming to get my miters nice and tight. Ben Blackmar gave me the idea of using strips of blue tape to make the final adjustments to the shop’s heavily-used miter sled.

The design for the box was heavily influenced by a box designed by Matt Kenney which also featured his technique for perfect grain-match miters.

As my first solo project, I’m very happy with the results. If I were to do it again, I’d leave even more space for the bottom to move. I’ll see just how tight it is when summer gets here.

Comments

Very good result for your first box. A good next step could be adding reinforcing splines on the corners. They add both strength and decorationl.

Dear Dillon;

A really nice job. But beware. Making boxes can become addictive. If you don't watch out, you will have them all over the house.

Best regards,

Richard Sandow

Looks great!

Log in or create an account to post a comment.

Sign up Log in