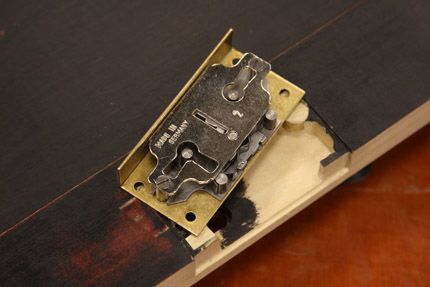

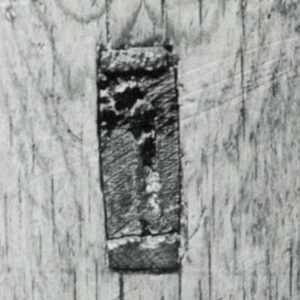

Yikes! This cherry cabinet's solid pine back was given 1/4-in. of expansion room in the grooves that house it, and yet it still blew out the dovetailed case! Hear more humidity horror stories and find out how you can prevent this from happening.

|

Every two weeks, a team of Fine Woodworking staffers answer questions from readers on Shop Talk Live, Fine Woodworking’s biweekly podcast. Send your woodworking questions to [email protected] for consideration in the regular broadcast!

Click on the link at left to listen to the podcast, or catch it in iTunes.

Shop Talk Live 36: Definitely a Dovetail Disaster

![]() On this week’s edition of Shop Talk Live, it’s a mano-a-mano battle to the end as Mike Pekovich and Ed Pirnik face off while regular STL contributors Asa Christiana and Matt Kenney sip on champagne coolies during yet another vacation! The guys fess up to some recent woodworking blunders, offer a few cool woodworking technique tips, and answer a variety of your woodworking questions.

On this week’s edition of Shop Talk Live, it’s a mano-a-mano battle to the end as Mike Pekovich and Ed Pirnik face off while regular STL contributors Asa Christiana and Matt Kenney sip on champagne coolies during yet another vacation! The guys fess up to some recent woodworking blunders, offer a few cool woodworking technique tips, and answer a variety of your woodworking questions.

Humidity Wreaks Havoc!

Also on this week’s show, Mike and Ed discuss a variety of wood movement nightmares, including busted joinery on a dovetailed cabinet, ever-expanding cabinet doors, and more. Learn why it happens, how to prevent it, and how to fix it!

Comments

1/4 inch of room for expansion? Was that a "this looks good enough" decision? When I'm deciding how much to allow I'll calculate expansion/contraction of whatever wood I'm using and *know* how much I *must* allow for.

The edges of wood boards always warp into the direction where the bark was, i.e. into the direction of the surrounding forest. Look at the annual rings. As far as I can see in the picture the rings of the tail board have their radius inside the cabinet. Just flipping the tail board over would surely have minimized the effect of these forces.

Regarding using plane shavings for tinder, I have been doing this in the barbecue. I have a chimney starter but instead of using newspaper a small paper bag full of plane shavings actually works much better. The wood shavings burn hotter and longer than paper but being dry they burn just as easily.

Regarding your old growth doug fir beam. I have a similar story.

I moved into a rented house and there was a 4x6x8' stick of doug fir sitting on the back fence just laying on the top rail of the fence, not attached to anything unfinished and grey with age, obviously a piece of forgotten stock. I took it into my shop and ran it through the planer and it turned out to be old growth with close to 200 rings per inch. Whoever left it there didn't know what it was. It's really a shame that this ancient tree was cut down to become fence posts.

Anyway I turned it into a nice console table. With 200 rings per inch it's as fine grained as mahogany.

So go for it! I didn't have to do any structural surgery but some of the best material is found material and you do it much more honor turning it into furniture than into fence posts.

A good case (pun intended) for using plywood for back panel on case.

Treating wood with PEG is supposed to reduce shrinkage by 80% true or false? PEG, I live in Guatemala, and PEG costs about $750.00 a 55 gallon barrel and that's the smallest amount they sell, "ouch".

Thanks for show.

Chuck

Here is another possible reason for the swirl marks from the random-orbit sander. After sanding with one grit, make sure to clean of the entire surface thoroughly, or an errant piece of grit could be left on the surface. That larger grit can make swirl marks in your board when you move onto a higher grit.

JPS: VERY good point about cleaning the surface between grits!

JKC: Getting ready to do the surgery on the garage door soon. Don't wory, I DO plan on replacing the beam! And then I've got to turn my attention to my attic: lifting up the floor boards, putting down new insulation, and then plywood sub floor. So I'll have LOTS of those old floor boards to play with. May have to show up at FWW with a truck full of wood!

Cheers,

Ed

Ed, you can drop those old floor boards in my driveway if you have too many. Just e-mail me and I'll give you my address. I hope it's not inconvenient that I live on the West coast.

Regarding the new music. The complainers need to turn in their ears, or get an education in music. Changing theme music occasionally doesn't hurt. But still, "bluesy" is adult????

BTW, moving cabinetry between southern and northern California, or between the coast and the interior can result in catastrophic failures: doors twisted into pretzels, panels jamming and then splitting.

Chris Becksvoort in his new dvd "A Craftmans' Guide to Understanding Wood" goes through exactly how to figure out how much to leave for expansion.

He mentions that he builds his furniture in Maine, but considers that the owner may eventually decide to retire and move to Arizona. He builds the pieces to handle such a change.

Log in or create an account to post a comment.

Sign up Log in