Is fitting drawers the best task in woodworking?

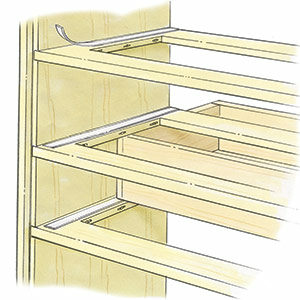

I think of fitting drawers as the dance of the handplanes. If they are sharp, it is a blast. Notice how I support drawer boxes for planing. Love that trick.

Fitting five drawers recently, planing each one for smooth action and perfect gaps all around, I realized that this is my favorite woodworking moment. Everything I’ve learned about making a square case, cutting good dovetails (on the tablesaw), honing blades and setting up handplanes comes together in a logical sequence of steps, all surprisingly easy. I’d like to know another woodworking task where the process is as fun and the payoff is as big–and you feel like such a magician!

Another way to look at it is that drawer-fitting is where you appreciate your handplanes most. You’ll need at least two of them, a No. 4 (smooth plane) and a shoulder plane, but it is really nice to have a few others.

Personally, I use an old Stanley No. 4 to knock down the protruding pins and tails and the hardened squeezeout around them before switching to my treasured bronze Lie-Nielsen No. 4, set up very tight with a delicate camber on the blade for the final smoothing and adjustments.

You could also use a No. 4 to clean up the top and bottom of the drawer box, and make sure the drawer isn’t rocking in its pocket, but I prefer the control of a block plane on those thin edges. I recently upgraded from a souped-up Stanley to a Veritas DX60. What a difference.

Once you have even gaps all around, the last step is to take a few passes on the lower edge of the drawer front. This prevents it from scraping, and also puts a nice fine gap there to match the ones on the sides.

Don’t fret about the unfinished drawer front. I am doing my half-blinds by laminating a thick veneer onto the front and trimming it flush afterward, just like Greg Paolini did in his fantastic recent article on tablesawn dovetails. My only difference from Paolini is using a blade with the tips ground to my dovetail angle, like Steve Latta showed way back when.

So how about you? What is your favorite woodworking moment?

Comments

Similar to yours, my favorite moment in constructing dressers, entertainment centers, and case goods is the moment when you have the carcase glued up. All of the dry fitting of components is done, and the frame is permanantly assembled. The time you spent dry fitting and figuring out a clamping strategy has paid off with a square case ready for doors, drawers and beautiful hardware. It's like that critical level on a game show which, once you achieve it, you can't fall below. All the progress you have made is now permanant, and you don't have to take it apart anymore for a last minute "tweak." As an added bonus, much of the sanding is already completed.

Any time I'm using my hand tools, is my favorite part of wood working.

Fitting drawers is also one of my favorite task. The sound of a well tuned wood plane slicing through the wood is music to my ears. Sawing and fitting the mortise and tenon joinery of a piece also ranks right up there. I don't think there's a part of the construction process that I don't like, except maybe finishing a piece and having to deliver it to the client. My wife says it's like I'm giving one of my children away.

I love that moment when the case is done, too. With a square case, everything else is gravy!

Ditto on square cases. When I was putting together my bench with its bank of drawers, I couldn't figure out why the carcase would not just drop in place between my clamped up leg-stretcher assembly. I triple checked my measurements, check. Checked the carcase for square, check. I mean, I was using i-beams to build up from then... it hit me. I checked the level again on the i-beams and there it was, one of the shims had scooted out of place. I tapped it back in place, hot melt glued it down then reassembled the legs & stretchers and VOILA! The drawer carcase slid home with a reassuring thunk. Everything is square. Whew!

As an old friend use to say, "Square is an enigma." How true that sentiment can be.

When I'm surrounded by sawdust, chips and shavings and a small, wooden monolith of specific character sits in front of me on my bench. Before finishing. When the shop smells like wood shavings.

When the piece is done there's a moment of sadness, until after I finish it and put it in the house, and we start using it. Then I sometimes touch it, remembering the energy I put into it, how it was born, what it has become.

So yeah, I get the child analogy :)

Log in or create an account to post a comment.

Sign up Log in