Lonnie Bird Style Workbench

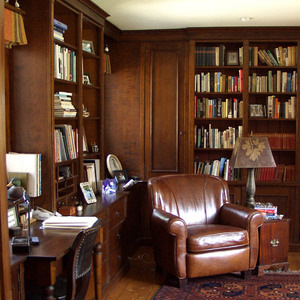

The finished bench. The rear vise jaw is buried in the front board of the top. This board is fastened with lag screws if I ever need to repair or remove the vise.

My new workbench is based on the ones in Lonnie Bird’s shop, with a few alterations. The finished bench is 37″ high, 8 feet long, and 26″ wide. The vise is the large cast iron vise from Lee Valley Tools. There is a planing stop on the left end and three hold fast holes in the top. The bench is constructed from 8/4 German Beech. The legs are 4″ square and the top is 3 1/4″ thick. The long rails are joined to the legs with mortise and tenon joints with 3/8″ threaded rods in the top and bottom of the rails. The short rails are joined with bolts and nuts. The only glue is in the top. It is finished with two coats of wipe on poly. The bench is very solid and does not budge when I’m planing. I’m very pleased with the bench and how it turned out. It has surpassed my hopes and expectations.

Log in or create an account to post a comment.

Sign up Log in