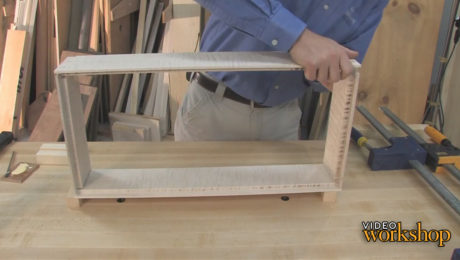

3 Steps to a Great Mortise-and-Tenon Glue-Up

Learn how to properly glue up mortise-and-tenon joinery.

Stopped Mortise-and-Tenon Joints: It’s one of the most common joints in furniture construction, yet most woodworkers tend to apply too much glue to their mortise-and-tenon joinery. Learn how to avoid nasty glue squeeze-out when assembling this workhorse of a joint.

Edited by: Gary Junken

Videos in the Series

-

3 Steps to Great Glue-Ups: Edge JointsOctober 31, 2012

-

3 Steps to a Great Dado-Joint Glue-UpNovember 2, 2012

-

3 Steps to a Great Mortise-and-Tenon Glue-UpNovember 16, 2012

-

Gluing Up Through Mortise-and-Tenon JointsNovember 19, 2012

-

3 Steps to a Great Dovetail-Joint Glue-UpDecember 3, 2012

-

Gluing Up Sliding Dovetail JointsDecember 6, 2012

Log in or create an account to post a comment.

Sign up Log in