Sweeping Curves

The simple, elegant lines of Adrian Ferrazzutti’s modern chair belie complex construction requiring an array of planing and belt-sanding jigs

At first glance, Adrian Ferrazzutti’s wenge-and-bloodwood chair (seen online and on the back cover of Fine Woodworking #194) is sleek, elegant, and simple in design. Yet the chair’s construction was anything but effortless. A deeper look reveals a coopered seat and backrest, compound angled joinery with wedged tenons, and twisted, tapered bent laminations. The coopering on the seat is straightforward, but Ferrazzutti felt that the backrest needed to be thinner at the edges and incorporate a taper–or two. If he were making one chair, it might have been quicker to just use hand tools. Ferrazzutti’s set of 10 chairs meant power tools and a variety of associated jigs.

Coopering the backrest

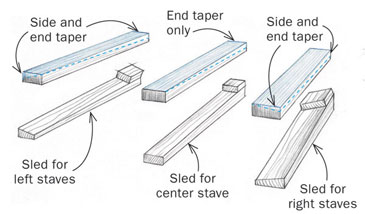

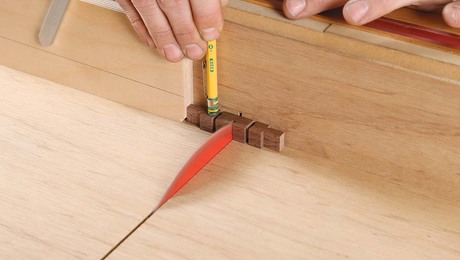

Twice-tapered staves. The center stave tapers only along its length, but the staves to the left and right have varying degrees of taper across their width as well. The edges are beveled prior to tapering. Click to enlarge.

A trio of sleds for tapering. Ferrazzutti uses three planer sleds to accomplish the double taper. One sled, with a taper along its length, is for the center stave. The other sleds are tapered side to side as well as along their lengths. Click to enlarge.

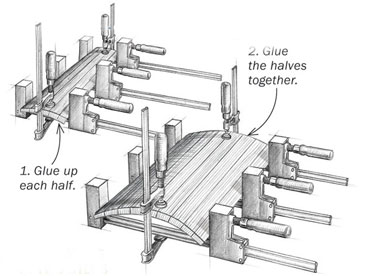

Glue panels in two steps. Working on half of the assembly at a time, Ferrazzutti uses bar clamps to secure the staves. Once dry, he glues the halves together. Click to enlarge.

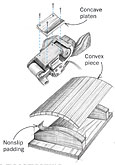

Sanding curved panels

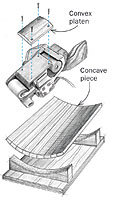

Curved sanding cradles with platens to match. Ferrazzutti builds a concave and a convex cradle to hold each piece for beltsanding. He lines the cradles with nonslip router matting for clamp-free sanding. He outfits his sander with a curved platen to match each cradle. Click to enlarge the image of the convex cradle or the concave cradle.

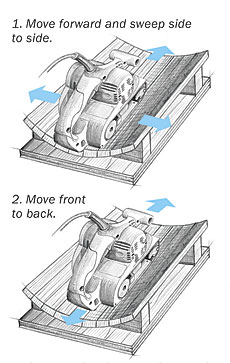

Moving the belt sander. Working with the curved-bottom belt sander, Ferrazzutti begins to sand side to side in a pendulum motion across the grain while slowly moving the sander up and down with the grain. He then sands lengthwise with the grain, removing any scratches, and does a final cleanup by hand with a curved sanding block. Click to enlarge image.

From Fine Woodworking #194

Photo: Ray Pilon; drawings: John Tetreault

Comments

A beautiful chair! I have sat in it too; quite comfortable for sure.

Log in or create an account to post a comment.

Sign up Log in