Curved Panels Made Easy

With a vacuum press and 7 tricks, beautiful panels are in the bag

Synopsis: Browse Michael Fortune’s gallery of furniture and you’ll quickly know that he’s an expert on curved work. His method for creating a veneered curved panel uses a veneer press and a shopmade bending form. Ribs, spacer blocks, and a cover sheet make the form strong enough to withstand the vacuum’s pressure and serve as a jig for routing the ends of the panel square. Fortune’s tips for perfect curved panels include using the vacuum bag to make the bending form itself, putting together a cross-grain sandwich for a rigid panel, using the form as a template to trim the ends, dialing in the edges with a digital gauge, banding the edges, and applying the face veneers one at a time.

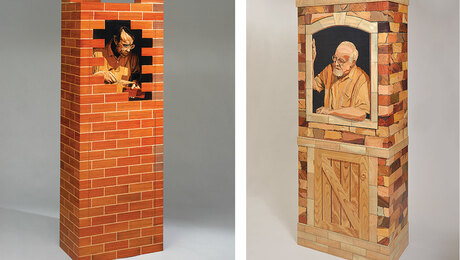

Furniture with curved panels stands out from the crowd. But common approaches to making them are imperfect. When made from solid wood, either by shaping thick planks or coopering thin staves, curved panels aren’t very stable. You can make a more stable panel by laminating several thin plies between a pair of forms, because the plies are arranged at right angles to one another. However, making the perfectly mated forms is tedious, and distributing pressure evenly across them is not easy.

The answer is a vacuum-bag system. With a vacuum press, you get the stability of a laminated panel but need only one form, and the press applies pressure evenly across the entire panel.

Most of my work is curved, and I’ve refined my techniques for making the form and panel. My methods are not difficult, and they allow you to pursue exciting design possibilities. I won’t cover the basics of buying and setting up a vacuum-bag system. That was covered in Part 1 (“A Vacuum Press Makes Veneering Easy,” FWW #208).

Simple materials work for most panels

Except for the edge-banding, a laminated curved panel is made up of glue, a core, and show veneer.

Titebond Cold Press for Veneer glue is great for laminating because it remains workable long enough to lay up the panel and get it in the bag. It’s also non-toxic, inexpensive, and flexible enough to accommodate the movement of the plies. However, when the show veneers are arranged decoratively, as with parquetry, the pieces are taped together and the grain can run in various directions. In these situations, I use Unibond 800 because its alcohol base greatly reduces the risk of the individual pieces rolling up or moving about.

Bendable plywood (also known as wiggle wood) is usually my first choice for the structural plies. It is extremely flexible: Pieces 3⁄16 in. thick can be bent to a radius as tight as 10 in.; 5⁄16-in.-thick pieces bend to a 14-in. radius. This material has three plies: a very thin inner ply sandwiched between two thicker plies. The grain on the outer plies runs in the same direction, which is why bendable plywood is so flexible. But you don’t want a floppy panel, so you add structural plies of veneer, laminated at a right angle to the grain direction on the outer plies of the bendable plywood, to lock it in the desired curve and make the panel stable. If the grain on the veneer and bendable plywood ran in the same direction, the panel would look like a potato chip.

From Fine Woodworking #210

For the full article, download the PDF below:

Log in or create an account to post a comment.

Sign up Log in