Assembly And Glue Up

-

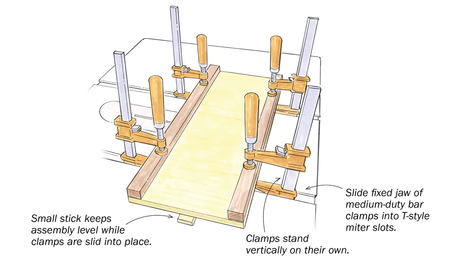

Stand large bar clamps in table-saw miter slotsFebruary 6, 2024

Stand large bar clamps in table-saw miter slotsFebruary 6, 2024 -

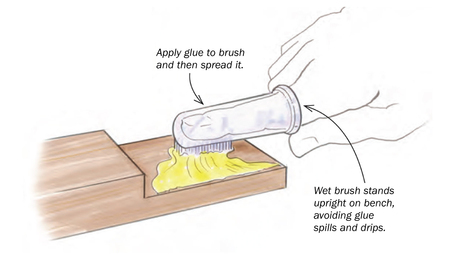

Fingertip toothbrushes make great glue spreadersOctober 2, 2023

Fingertip toothbrushes make great glue spreadersOctober 2, 2023 -

Tips for creating custom clamping blocksSeptember 27, 2023

Tips for creating custom clamping blocksSeptember 27, 2023 -

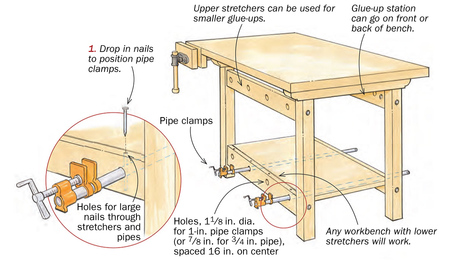

Use your workbench as a vertical glue-up stationApril 12, 2023

Use your workbench as a vertical glue-up stationApril 12, 2023 -

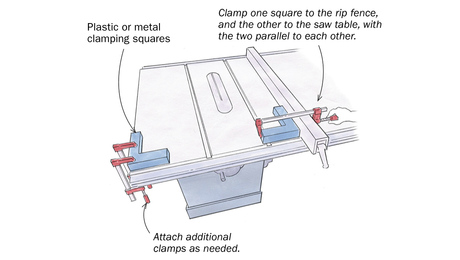

Workshop Tip: Use your rip fence to assemble boxesNovember 9, 2022

Workshop Tip: Use your rip fence to assemble boxesNovember 9, 2022 -

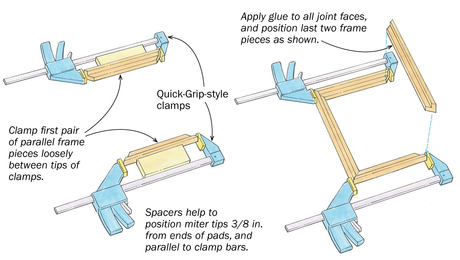

Workshop tip: Quick-Grip-style clamps assemble miters quickly and accuratelyAugust 10, 2022

Workshop tip: Quick-Grip-style clamps assemble miters quickly and accuratelyAugust 10, 2022 -

Woodworker’s guide to glueJanuary 3, 2022

Woodworker’s guide to glueJanuary 3, 2022 -

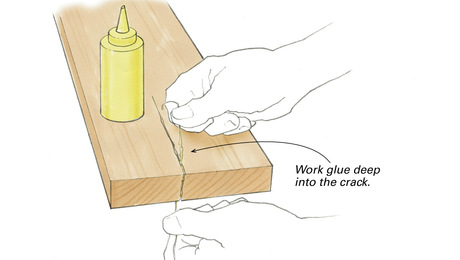

Workshop tip: Dental floss works glue deep into cracksJuly 1, 2021

Workshop tip: Dental floss works glue deep into cracksJuly 1, 2021 -

Make a Veneered Box with Contrasting Miter Keys, Part 2April 5, 2021

Make a Veneered Box with Contrasting Miter Keys, Part 2April 5, 2021 -

Handplaning With PrecisionDecember 22, 2020

Handplaning With PrecisionDecember 22, 2020